|

|

PRINT » |

|

|

E-MAIL THIS PAGE » |

|

|

CLOSE THIS WINDOW » |

Feature Article from the June 2007 Magazine Issue

T'ain't Necessarily Corks

Prevention and eradication of winery TCA

Thanks to a series of high-profile exposures, the problem of systemic TCA--the same moldy menace, but spread throughout an entire winery, not just housed in individual corks--has become a critical industry issue. Winery TCA has emerged as a high-stakes concern: not always easily detected, costly to eradicate, potentially damaging to winery sales and reputations, and yet another source of friction between winemakers and wine critics. And it will not be easy to put this particular "cork" back in its bottle.

The bad actor in this winery drama, 2,4,6-trichloroanisole (stage name TCA), is created by interaction between fungi and chlorophenols,compounds which can be generated through the use of chlorine for bleaching and sanitation. Mixing very badly with wine phenolics, TCA can make a wine reek of mold--wet newspaper is a common descriptor--or in smaller quantities, strip the wine of its fruit and flavor. TCA is an incredibly powerful odorant, detectable by most wine consumers at a level of less than 10 parts per trillion (ppt). Purdue enologist Christian Butzke once estimated that a tablespoon of pure TCA could render all the wine in the United States undrinkable.

Hanzell Vineyards handled TCA with a thorough clean-up and new winemaking facilities, but retained its emblematic façade and its customer loyalty, mounting a textbook perfect PR campaign.

Thresholds for different individual tasters vary widely; sensitive palates may pick up TCA at one or two ppt, while many other drinkers may not notice anything funny until six or eight ppt. For the broad consumer market, where the mechanics of TCA taint are not well understood, contamination usually just means drinkers dislike the wine or find it unpleasant--laying the blame on the winery, the grape variety or the region of origin, not on TCA.

'Corky,' But Not From Corks

For the past couple of decades, the delivery vehicle for TCA was assumed to be corks. Cork oaks can be affected by chlorophenols in industrial pollution; more importantly, chlorine was used in the past, ironically enough, as a means of sanitizing cork. Studies indicated that somewhere between 3% and 7% of cork-bottled wines showed evidence of TCA. The association of corks with TCA led to nicknaming the malady "cork taint" and calling the wines "corky;" the difficulty in eradicating it entirely from supplies of natural corks gave the main impetus to the recent rise in popularity of synthetic corks and screwcap closures.

Cork taint, however, turns out to be something of a misnomer. TCA can be created by almost any combination of chlorophenols, airborne fungi and materials containing cellulose. That's a pretty good working definition of a winery, at least until recently: widespread use of chlorine-based cleaning products; lots of ambient microbes; row upon row of barrels, cardboard boxes and wooden pallets; and wine just waiting to be infected. It can be just as voracious as Brettanomyces or volatile acidity, and proper use of SO2 won't take care of it. Winery TCA--sometimes called ambient or systemic--doesn't just affect a bottle here and a bottle there--it can affect entire lots of wine or even entire wineries.

The real problem lies with relatively low levels of ambient TCA. If a wine facility truly reeks, sooner or later someone will blow the whistle and take steps to correct the situation. At low levels, confined perhaps to just one section of a winery, TCA may not be noticed, blending its way into the "house smell" that winery staff get used to and assume is normal.

Extensive renovations were necessary to clean up a 2004 TCA invasion at historic Chateau Montelena: older tanks, barrels, racks, pallets and ladders and in-ground plumbing were replaced, and stone surfaces were hand-cleaned.

Fixing the Problem

Eliminating the sources of TCA contamination in a winery is expensive, complicated, hard work. Hanzell, one of the first wineries to be "outed" for low-level TCA, basically built an entirely new winemaking facility. Michael Terrien, now Hanzell's winemaker (Bob Sessions was the winemaker during the TCA crisis), says that once it was established that the winery had a TCA problem, no one could find the smoking gun--many infected areas, but no single source. TCA could be found in barrels, wooden water tanks, drains, hoses, the air conditioning system.

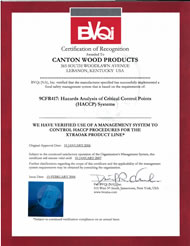

Canton Wood Products of Lebanon, Ky., received certification in January 2006 from an international third-party agency, Bureau Veritas, for its XtraOak product line after a year and a half process. The certification attests that Canton is using a detailed management system for Hazards Analysis of Critical Control Points. Bureau Veritas essentially audited the results of Canton's extensive inspection and testing process at the XtraOak facility in Kentucky, and approved them. Jean Vittot, the Napa-based vice-president of sales for Canton, Jacques Garnier and XtraOak divisions of Chene et Cie., said that the Canton Cooperage, also in Lebanon, Ky., and the Taransaud cooperage in France follow the same procedures, but have not been certified. "We are confident we are supplying barrels and oak alternatives free of those nine chemicals known to give bad smell and bad taste to the wine." Vittot said Canton takes statistical samples of all raw materials and purchased supplies, and tests them for TCA, TeCA, TBA, PCA, TCP, TeCP, PCP, TBP and Lindane. The company samples the building structure, traps air samples from manufacturing and storage facilities in bentonite, filters chlorine out of the water and sends all these to outside labs for regular analysis. Random samplings of the finished products are routinely analyzed. The shipping containers used for Taransaud and Canton products are also tested, he said. The process also confirms the origin of the oak and length of air seasoning for French oak, and the length of air seasoning for American oak but not the origin. Many coopers do the same or similar tests. Vittot said that one reason to take the extra step of certification was to satisfy winery customers in Australia, who are especially demanding of quality control standards. |

"Everyone was left with the feeling that 50 years of cleaning with chlorine had created an environment that encouraged TCA," Terrien says. Wood and stone surfaces were laboriously scraped; hoses, drains and the air conditioning were replaced. After all that work and expense, the cleaned-up old winery is now mostly used to demonstrate Hanzell's proud history; the wine is made in another building.

When Chateau Montelena's turn came in 2004, extensive renovations were also undertaken: replacement of older tanks, barrels, barrel racks, pallets and ladders; hand-cleaning of stone surfaces and replacing all the in-ground plumbing.

Preventing the onset or recurrence of systemic winery TCA doesn't require such dramatic changes, but it does mean constant scrutiny of anything that might lead to trouble. First and foremost, wineries need to discontinue any use of chlorine-based cleaning products. The most common replacement is peroxide-based cleaners. Keeping chlorine out of the water supply, or at least any water that comes near winemaking--rinsing out barrels, cleaning tanks, hosing down barrel-room floors--is also an important step.

Terrien says that he and the rest of the staff at Hanzell investigate any new material that comes into the winery. "We have a practice of zero tolerance for materials that could absorb TCA. No chlorine, of course. But we also use concrete barrel chocks, not wood. Rental equipment gets checked. We are trying to encourage suppliers to use plastic pallets, but with no luck so far. We soak a statistical sample of barrels with water, and then analyze the water for TCA. We ask our cooperages what procedures they use to inspect, analyze and take care of their barrels."

With a clean winery, and procedures in place to keep it that way, there's still the problem of that TCA-impacted wine. There's a nifty home remedy for single TCA-ridden bottles: pour the wine in a bowl, crumple in a couple feet of Saran Wrap and stir--the polymers in the plastic pick up the TCA. Until recently, wineries did pretty much the same thing, stuffing yards and yards of plastic sheeting into tanks and circulating the wine. These days, the more likely option is filtration--sending the wine across a medium containing TCA-grabbing polymers. VA Filtration in American Canyon, Calif.; Filtrox North America, in Kirkland, Wash.; and Winetech in Napa are among the companies that provide mobile services. Winetech says that its polyethylene polymers will also capture TBA--2,4,6-tribromoanisole--another stinky compound derived from wood preservatives. To cleanse large wine lots, some wineries do a fining with half and half; the extra butterfat snags the TCA.

Elementary business sense suggests every winery should do testing to find out whether TCA is present in its facilities and equipment. Samples of wine or winery water can be tested for about $100 a pop; testing every barrel in the winery isn't economical, but testing a small, representative percentage is probably worth it. The worst way to find out about a TCA problem on your premises, of course, is to read about it in the wine press, and anyone who sends off samples and participates in the wine ratings game is taking that chance.

There are no statistics on how many wineries in the U.S. have a TCA problem. But all the people I talked to for this article who have expertise in the area--laboratory analysts, and winemakers who've been burned--say they are amazed at how often they walk into a new winery and sniff TCA in the air. There is undoubtedly a good deal of wine out there on the market that contains extremely low levels of TCA that no one has noticed--but it's probably just a matter of time.

| The way in which the winery TCA issue has surfaced--through exposure in the wine press--has added its own dimension to the story. What is the propriety of "outing" wineries that were, up until that point, selling their wine readily and getting good scores? Can everyone detect low levels of TCA, or just "super-tasters," and should that select few set the standard? And once a wi

nery has received this unwelcome spotlight, how should it handle the public relations fallout? Almost all of the fuss centers on one particular wine critic, James Laube of the Wine Spectator. Laube clearly has a high degree of sensitivity to TCA, identifying it at extremely low levels (under two parts per trillion) and he also strongly feels that consumers should be made aware of wines that contain TCA. Laube's method has always involved testing of the wines in question by outside labs, as well as discussions with winery owners and staff, and in every case he has been right--that is, the wines did contain TCA and not from corks. But if Laube is the only one who can taste TCA at these very low levels, is there really a problem? Individual thresholds vary widely, and the great majority of consumers would probably not find the levels of TCA in most of the wines Laube has criticized objectionable. According to flavor chemist Leslie Norris of FlavorSense, studies show that consumers can detect that "something" is different about a TCA-doctored white wine at about 2.1 to 2.4 ppt; it takes a higher level, more like 3 ppt, before drinkers reject the wine; and a still higher level, 4.4-6.5 ppt, for consumers to recognize the fault as TCA. Red wines with more complex aromatics can probably "hide" slightly higher levels. It is even possible for some consumers to associate a tiny whiff of TCA with some pleasurable memory or tradition, turning it into a positive attribute. Clearly it is quite possible for wines with low levels of TCA to succeed in the marketplace. But for premium and ultra-premium wines--bottles that are tasted and reviewed by influential critics and writers-- there is always the chance that the undetectable level of TCA will be detected and publicized. At which point a wine that had no functional problem has two: one in the winery and one in the arena of public relations. Experience indicates that wineries facing the glare of TCA exposure need to deal with the problem forthrightly and publicly. This is the road Hanzell took. Winery president Jean Arnold Sessions insisted that everything in response be done openly and above board; that the results of testing be disclosed and that lessons learned be shared with other wineries. Demonstrating its seriousness, Hanzell took its wines off the market for nine months while sorting out complex issues--not only how to rehabilitate the winery, but whether the wines should remain on the market or be replaced with other vintages. Chateau Montelena also responded in a very straightforward fashion, though with a slightly different strategy. Since the TCA levels in the Montelena wines--which the winery acknowledged--were extremely low, and since other major critics, including Robert Parker, had rated the same wines highly, Montelena continued to maintain that these were excellent, noteworthy wines. Tastings were held around the country for trade and press people, who for the most part validated Montelena's positive assessment. Meanwhile, the winery underwent a substantial renovation, making every effort to reduce the level of TCA to near zero. Public relations veteran Michael Fineman, who worked with both Hanzell and Montelena in these crisis management situations, says that making the full extent of the problem--and the solutions--public is essential; the "duck and cover" approach that some wineries had tried in the past never worked. "If you don't handle the problem directly, people stop trusting you. Spin doesn't help in the long term." |

|

|

PRINT » |

|

|

E-MAIL THIS ARTICLE » |

|

|

CLOSE THIS WINDOW » |