|

|

PRINT » |

|

|

E-MAIL THIS PAGE » |

|

|

CLOSE THIS WINDOW » |

What Makes Hungarian Oak Barrels Unique?

A visit to the Zemplen forest sheds light on their quality and characteristics

The oak forests and stave mills of Hungary account for only about 4% of world wine barrel production, but the central European country is getting more than it's share of attention and acceptance from winemakers these days. That's due to the increasing quality and distinctive flavor characteristics of those barrels, not to mention their moderate prices.

While less expensive than their French counterparts that average more than $900 each, Hungarian oak barrels average just under $800 and are generally still more expensive than American oak barrels, which average $500 apiece. How have Hungarian barrels narrowed the price gap with French ones? Where does the spicy profile that Hungarian oak often gives to wine come from? Is all Hungarian oak alike?

Last spring, a small group of West Coast winemakers embarked on an oak-oriented tour of Hungary with well-informed executives of the Kádár Hungary cooperage who helped answer those questions. In a nutshell, Hungary’s geography and climate differ significantly from that of France, and Hungary’s native oak species differ completely from those of North America.

Quercus robur vs. Quercus petraea

Quercus robur vs. Quercus petraea

The two main European oak species used for barrels are Quercus robur, also known as pedunculate oak, and Quercus petraea, also known as sessile oak. The trees appear somewhat different, especially their acorns. Acorns on the Quercus robur are attached to branches by a little stem or pedicle, hence the name pedunculate. Acorns on the Quercus petraea sit directly on the branches, and sessile refers to sitting.

Oak sellers and buyers will sometimes use the scientific names and other times the supposedly common names, which are not at all common in American English. We will use the species names here: robur and petraea.

András Kalydy is the managing director of Kádár Hungary, one of the country’s largest and most respected cooperages. Educated as a metallurgical engineer, Kalydy joined Kádár in part because he had fond childhood memories of exploring the oak forests with his grandfather, a forester who managed hundreds of thousands of acres.

He explained that petraea is known for producing barrel staves that give a pronounced aromatic character and low tannin content to wine. Robur provides fuller body and more tannin structure while giving less complexity and less elegance than petraea, he said. American oak barrels use Quercus alba, or white oak, to which many winemakers attribute a sweet, spicy flavor.

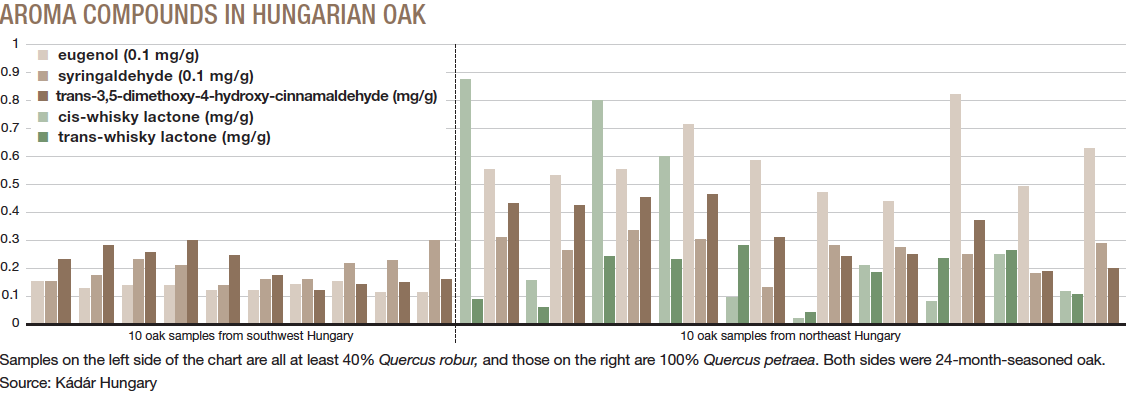

Graphs showing chemical analysis of aroma compounds in Kádár staves made from the two different species of oak (page 38) show dramatic differences. These chemical analyses corroborate the sensory evaluations of many winemakers. “The differences were stark and consistent by species,” said Peter Molnar, an American with Hungarian roots, whose family co-owns Kádár.

The two European species grow in various parts of Europe, often intermingled, and they crossbreed very easily. Kalydy said few forests have a high majority of one or the other species. The Limousin forest in south central France is one of those: Its oak population is close to 100% robur, he said. Limousin oak is used primarily for Cognac production but sometimes for wine.

Tronçais vs. Zemplén

Another French forest, the Tronçais, is at almost the exact center of France and is unusual for having a high proportion of petraea oak. However, according to Kádár’s calculations, the Zemplén forest in the mountains of northeast Hungary near the winemaking region of Tokaj tops Tronçais with 95% of the oak trees being petraea. “Tokaj forests are absolutely unique in Europe in being so Quercus petraea dominant,” Molnar said.

The two European species prefer different living conditions, Kalydy said. Robur performs best with more water, richer soil and more nutrition and gives a stronger flavor to wine. Molnar added, “Which is where it got its Latin name: stronger, more robust.” Petraea can survive and grow with fewer amenities in thinner soil, colder temperatures and with longer winters. The root meaning of the word refers to rocks.

“Petraea was from the rocks, on the ridges,” Molnar continued. “After the last ice age, the glacial moraines were formed, and the pH of the moraines was great for the regrowth of oak. Robur would grow along large river courses, and the petraea would kind of hop from mountain to mountain. So Tronçais and Tokaj were the only two forests that were isolated from these large river courses, and that was why they ended up with more petraea than they did robur.”

The Zemplén forest covers the foothills of the Carpathian Mountains, where the best cooperage oak grows between about 1,200 and 2,100 feet elevation. “This region had recent volcanic activity,” Kalydy said. It was between 6 million and 8 million years ago, so some of the youngest volcanic flows in Europe are in the Carpathians, which reach 11,000 feet in some places.

He said the winters in the Zemplén forest are much longer than in southwest Hungary, where Kádár and other coopers also harvest oak, including a much larger percentage of robur. In the southwest, the Mediterranean influence moderates the climate, and the terrain is less mountainous and more fertile. More trees here are hybrids of the two oak types. In contrast the Zemplen, where Kádár gets about 40% of its trees, has about twice the number of snow-covered days as well as thin, rocky soil with little organic matter.

Because of the difficult growing conditions, petraea trees in the region grow very slowly, and the wood grain is very tight, a trait almost universally considered desirable for aging high-quality wine. The tall, slender petraea trees in the Zemplén are harvested at 80 to 120 years old. They have 15 rings per inch of diameter and measure just 14 inches average diameter, which is much smaller than the average size of French trees of the same age, Molnar said.

Tight grain = aromatics

“We do know that the triumvirate of the cold climate, high altitude and young volcanic soil creates a profile we like in the oak, and aromatic impact is the No. 1 driver,” Molnar said. Not that the aromatic impact comes from something in the soil. He maintained that the species and tighter grain of the wood are the keys.

The grain is determined by the thickness of the growth rings. Each growth ring consists of a portion of early season growth and later season growth. Molnar maintained that petraea trees in the Zemplén forest are stressed for nutrition and water and grow mainly in the early season. “Tight grain is always more aromatic, because all the aromatics are basically in the spring wood,” he said. The summer wood is “structural” and doesn’t add many aromatics; it is extra wood that dilutes the impact of the spring wood, he said.

The grain is determined by the thickness of the growth rings. Each growth ring consists of a portion of early season growth and later season growth. Molnar maintained that petraea trees in the Zemplén forest are stressed for nutrition and water and grow mainly in the early season. “Tight grain is always more aromatic, because all the aromatics are basically in the spring wood,” he said. The summer wood is “structural” and doesn’t add many aromatics; it is extra wood that dilutes the impact of the spring wood, he said.

Kádár also sources a portion of its wood from Slovakia, over the border that lies about 25 miles away to the north. “The conditions are the same. It’s all a part of the Inner Carpathia Volcanic Mountains and the trees don’t know about the border,” Kalydy quipped.

Just 5% of the trees are suitable for barrels, and cutting is limited to sections no bigger than 5 hectares at a time. Loggers harvest only the straightest trees and those that have few or no branches lower than about 40 feet up the trunk. One tree produces enough stave wood for a little less than one barrel, and one hectare produces no more than 10 barrels every 100 years.

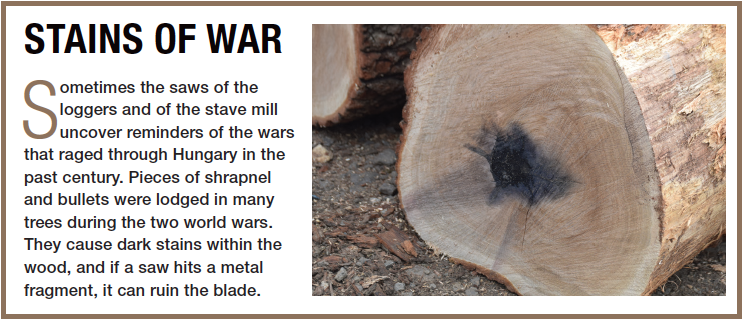

Government foresters regulate the practices of the loggers and allow coopers to choose and buy logs directly from the forest or at auction. Forest land can be owned by the national government, private companies or local authorities.

Forest owners are required to improve and protect the oak crop. Each forest region has a 10-year plan that is checked every year. Periodically, block by block, foresters remove underbrush and thin the oak trees to give the promising ones room to catch the sun. Harvest is done in the winter, when the activity is less of a threat to young saplings. Horses drag out some of the logs in steep terrain since they cause less erosion than tractors.

Forest owners are required to improve and protect the oak crop. Each forest region has a 10-year plan that is checked every year. Periodically, block by block, foresters remove underbrush and thin the oak trees to give the promising ones room to catch the sun. Harvest is done in the winter, when the activity is less of a threat to young saplings. Horses drag out some of the logs in steep terrain since they cause less erosion than tractors.

During the harvest, not all the trees in a block are taken. Not all of them are suitable for coopering, and the regulations also require that “mother” trees be left standing for 20 years so their acorns will re-seed the block. The biggest part of the volume of wood that’s cut becomes firewood for local homes, andthe heartwood is used for high-end furniture and barrels.

Hungary has a 1,000-year tradition of barrel-making and a longer one of winemaking. The oak forests have been regulated by the government since empress Maria Teresa of the Austro-Hungarian empire promulgated the Forestry Law of 1769. The 100-year cutting cycle was established then, and many of the regulations today are direct descendants of the Forestry Law, Molnar said. (France dates its government control over forests to 1669.)

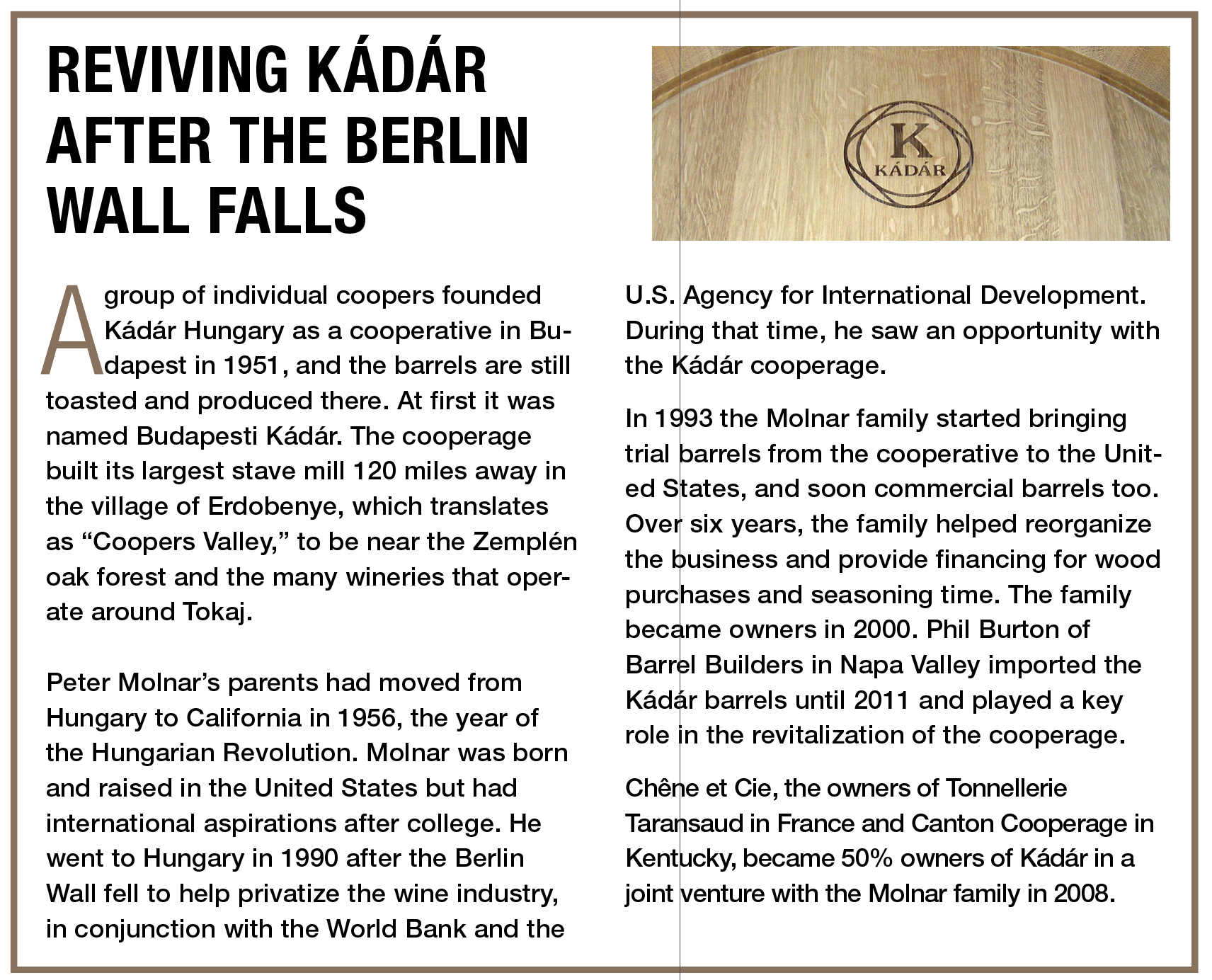

Barrel-making and many other aspects of Hungarian life werestifled by the Soviet Union’s domination of the country for much of the 20th century. Only after the Berlin Wall came down did Hungary and other central and eastern European countries have a chance to restart businesses and reach out to markets beyond the Iron Curtain.

About a dozen cooperages operate in Hungary, and numerous cooperages elsewhere make barrels from Hungarian staves. Total volume for Hungary is 30,000 barrels per year, and in 2017 Kádár made 6,000 barrels that supplied 400 wineries in 12 major winemaking markets.

Seasoning staves among trees

Kádár’s focus recently has been on transforming the stave yard—and with it the stave-seasoning process. Encouraged by the experience at sister company Taransaud’s operations in Cognac, Kádár has moved its logs and stacks of staves into the forest, or at least next to it, for seasoning. The idea is that the wood should be seasoned in an environment similar to where the oak trees grow, to encourage the humidity and beneficial microflora (bacteria and microscopic fungi) that do most of the work of seasoning.

“The maintenance of the biological population throughout the 24- or 36-month period is the absolute key to having well-seasoned wood,” Molnar said. The Taransaud team did numerous experiments to see how best to protect staves from extremes of weather and climate change and support the microflora—trying fences, shade covers and other methods—but finally observed that the most effective solution was to have trees nearby. “They are now planting trees around their stave yard in Cognac,” he said. “We already had trees, so we decided let’s put our oak as close to the trees as possible to maintain this envelope of biology around us.”

The Kádár stave mill is on the edge of the village with forest on two sides, so Kádár bought an 8-acre piece of the adjoining woodland and laid out a park-like setting with islands of trees, next to which the logs may rest for three to six months—and the stave wood longer. Kádár puts a lot of emphasis on keeping the wood humidified. There is no pavement or gravel, just a natural earth surface that releases moisture back into the air after rains.

A few other steps in the barrel-making process also distinguish Kádár barrels. The coopers do a long, slow toasting of the barrels over oak wood fires and use a sensor that Kádár developed to measure the temperature

inside the staves so they know exactly when to stop. The slow toast matches the already highly aromatic nature of Hungarian oak, Molnar said. “We emphasize high tones and get away from toastiness. Deep, heavy toasting can dampen the barrel’s ability to preserve freshness and tension in the wine. We have progressively gone for lower firing temperatures over time.”

A few other steps in the barrel-making process also distinguish Kádár barrels. The coopers do a long, slow toasting of the barrels over oak wood fires and use a sensor that Kádár developed to measure the temperature

inside the staves so they know exactly when to stop. The slow toast matches the already highly aromatic nature of Hungarian oak, Molnar said. “We emphasize high tones and get away from toastiness. Deep, heavy toasting can dampen the barrel’s ability to preserve freshness and tension in the wine. We have progressively gone for lower firing temperatures over time.”

The evolution of Kádár’s barrels and barrel-making practices represent improvements seen across a wide swath of the cooperage industry in Hungary. In fact, they’re not a bad example for the Hungarian wine industry and economy in general. Winemakers in North America had some disappointing experiences with Hungarian barrels in the 1990s and 2000s, but those are now fading into the past, and a look at the forests and cooperages of the ancient winemaking country shows how Hungarian barrels have earned a place in the barrel programs of so many wineries today.

|

|

PRINT » |

|

|

E-MAIL THIS ARTICLE » |

|

|

CLOSE THIS WINDOW » |