|

|

PRINT » |

|

|

E-MAIL THIS PAGE » |

|

|

CLOSE THIS WINDOW » |

Wheeler Farms

Well-equipped custom-crush facility in Napa Valley is a new start for former owners of Araujo Estate

As Bart Araujo was talking about the vision behind his new winery in Napa Valley, he had to pause and make sure a concrete truck was able to make it through the correct gate at the property.

As Bart Araujo was talking about the vision behind his new winery in Napa Valley, he had to pause and make sure a concrete truck was able to make it through the correct gate at the property.

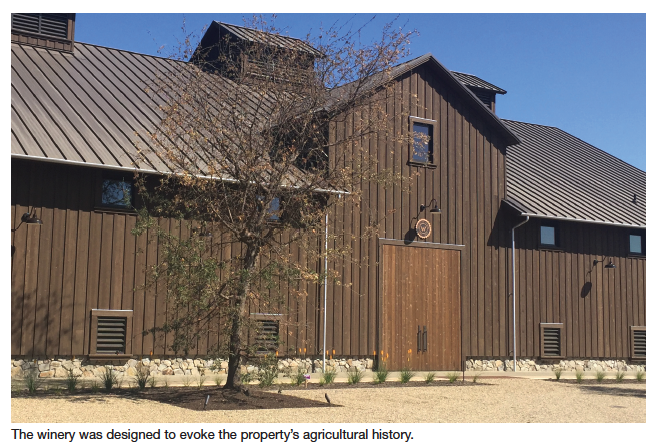

When Wines & Vines visited on a warm afternoon in mid-July, not everything was finished, and the truck was there to pour concrete for a chicken coop, shed and other outbuildings that would be clustered near a fruit orchard. The chickens, orchard and a planned vegetable garden are intended to support the winery’s commercial kitchen as well as evoke the property’s past.

When husband and wife Bart and Daphne Araujo purchased the 12-acre property on Zinfandel Lane southeast of St. Helena in 2013, they were buying the last parcel of the historic Wheeler Farms, which in the 1800s stretched over 2,000 acres and included a winery that was established in 1880. Back then, the ranch had its own railroad depot, Zinfandel Station, and a mix of crops that included prunes and table grapes.

When husband and wife Bart and Daphne Araujo purchased the 12-acre property on Zinfandel Lane southeast of St. Helena in 2013, they were buying the last parcel of the historic Wheeler Farms, which in the 1800s stretched over 2,000 acres and included a winery that was established in 1880. Back then, the ranch had its own railroad depot, Zinfandel Station, and a mix of crops that included prunes and table grapes.

The property came with 9 acres of Cabernet Sauvignon, but Araujo removed a half acre of vines for the garden because it was so important to him to have a bit of agricultural diversity. In addition to the garden, he also imported 80 olive trees. “The concept here is we wanted to have a state-of-the-art winemaking and hospitality facility, but we wanted the architecture—both building and landscape—to be reflective of the historical nature of the property,” he said. “I really wanted people to have an agricultural experience, not just a wine experience.”

The Araujos bought the property after they sold their namesake winery, Araujo Estate, and the famed Eisele Vineyard near Calistoga to Artémis, the holding group founded by French billionaire Francois Pinault. Artémis also owns Bordeaux first growth Chateau Latour, Chateau Siaurac in Bordeaux, Domaine d’Eugenie in Burgundy and Chateau-Grillet in the Rhône Valley.

The Eisele sale took place in 2013. At the time, the Araujos said they planned to invest in vineyard property and continue to make wine. They had no plans to build a winery.

But serendipitously, the couple learned of an opportunity to buy the Wheeler Farms property, which was already approved for a winery permit.

Land, plans and a permit

A group of Japanese investors had decided to abandon its plans for a new winery and was ready to sell. The winery permit allowed for a 50,000-gallon winery, commercial kitchen and a generous number of events and annual visitors. The permit had been granted shortly after the recession, when Napa County officials were eager to allow new wineries to be built. The permit had remained viable because the original partners had invested enough over the years in planning and architectural work.

“We knew we were going to make wine, but having a new winery wasn’t really high on the priority list. Then this came along, and it was perfect,” Araujo said. “All that heavy lifting was done, so it was very attractive and it allowed us to really create a new state-of-the-art facility for making our wine.”

The property purchase came with an architectural design by the firm Taylor Lombardo Architects, which has offices in San Francisco and Napa and has designed several wineries.

Araujo envisioned the winery not just as the home of his family’s new brand, Accendo, but also as a home for several other wineries. He saw the potential of a custom-crush operation (or atelier, as he likes to call it) for a “group of like-minded people who are all true artists in their profession, which in this case just happens to be winemaking.”

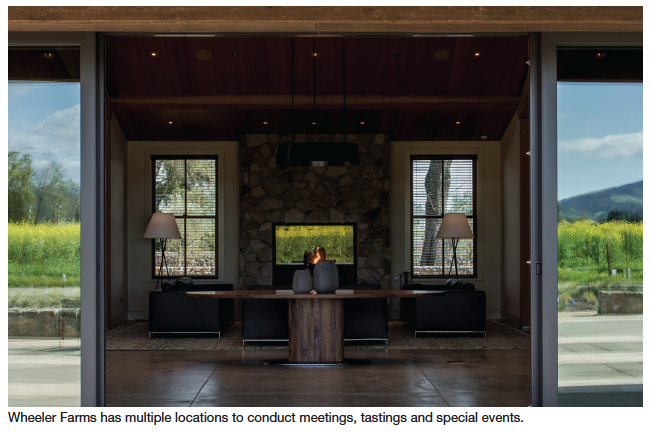

To provide the space for the type of winemaking studio Araujo wanted, the plan had to be tweaked just a bit for extra barrel-storage capacity. From Zinfandel Lane, the wood-clad winery building could almost be mistaken for a private home. Tastings and other hospitality functions take place in a separate, 2,569-square-foot building on the eastern side of the property, and the barn-like winery is in the center with winemaking offices to the west. The winery and office building are linked by a roof that covers the grape-receiving area. The winery covers nearly 10,000 square feet, and the two-story office offers 3,600 square feet of space.

Running the length of the production areas is a multi-room, underground 14,500-square-foot barrel cellar. Araujo said the cellar was the major revision to the original plans for the winery. He and his team had to expand the footprint of the building, but the permitted capacity is still likely more than he and the other clients need.

While everything on the outside of the winemaking structure is rustic wood, inside it’s all business and near-pharmaceutical-grade steel.

Construction of the winery and hospitality building was managed by Santa Rosa, Calif.-based Wright Contracting and began in 2015. The landscape architect was Lutsko Associates, and civil engineering was done by Bartelt Engineering. The winery was finished in time for the 2016 vintage, during which a few clients processed grapes. “We wanted to make sure everything worked. We had all this great state-of-the-art equipment, but it had never been hooked up together,” Araujo said. “Everything just worked beautifully.”

Araujo worked with consulting winemaker Nigel Kinsman, who had previously consulted for Araujo Estate, on the design and equipment of the winery. Sarah Donley, who interned at Araujo and then went on to work at Colgin Cellars for several years, is the on-site winemaker and production manager. Cesar Sandoval, cellarmaster at Araujo for 10 years, is the cellarmaster at Wheeler Farms. “We just have an incredible winemaking team,” Araujo says.

Araujo worked with consulting winemaker Nigel Kinsman, who had previously consulted for Araujo Estate, on the design and equipment of the winery. Sarah Donley, who interned at Araujo and then went on to work at Colgin Cellars for several years, is the on-site winemaker and production manager. Cesar Sandoval, cellarmaster at Araujo for 10 years, is the cellarmaster at Wheeler Farms. “We just have an incredible winemaking team,” Araujo says.

Premium facility

for premium grapes

After selling Eisele, the Araujos purchased the Rancho Pequeno vineyard in Oakville for Sauvignon Blanc and Cabernet Sauvignon grapes for the Accendo brand. Accendo also uses grapes from three other Oakville vineyards and two Oak Knoll vineyards. Araujo said he buys

from other growers he respects and who share his vision of producing elegant, classic wines. He also stressed that in making Accendo at Wheeler Farms he does not receive or expect to receive any special consideration, and the company is paying all the same custom-crush fees and is bound by the same tenant parameters as all the other alternating proprietor wineries.

Araujo produces Accendo with winemaker Francoise Peschon, consulting winemaker Michel Rolland, viticulture consultant Steve Matthiasson and Biodynamic consultant Jeff Dawson.

Accendo production is currently about 1,350 cases, with a little more than half being Sauvignon Blanc. Cabernet production will increase only as the Araujos gain access to vineyards they’d like to source from, as the goal is to make wines that show “elegance, balance, freshness and finesse,” and which are blended from multiple vineyards. Nearly all production is sold direct to consumer with some limited placements in Napa Valley, other California markets, New York and Texas.

Accendo production is currently about 1,350 cases, with a little more than half being Sauvignon Blanc. Cabernet production will increase only as the Araujos gain access to vineyards they’d like to source from, as the goal is to make wines that show “elegance, balance, freshness and finesse,” and which are blended from multiple vineyards. Nearly all production is sold direct to consumer with some limited placements in Napa Valley, other California markets, New York and Texas.

Wheeler Farms is owned by the Araujos and a few other partners, and the business entails custom crush, the hospitality center and the Wheeler Farms brand. Donley oversees winemaking of the Wheeler Farms brand.

All the other companies making wine at Wheeler Farms are using grapes from Napa Valley, where the average price for Cabernet Sauvignon is about $7,000 per ton and folks don’t blink at $10,000 per ton.

Araujo said including the land, construction and equipping the winery, the total investment comes to around $30 million. Because he and his clients are using such exceptional grapes, he wanted a facility to match that quality.

The administration building houses offices as well as a spacious room for a lab that will eventually contain all the equipment needed for extensive wine analysis. Araujo said all analysis is still being sent out to ETS Laboratories this vintage, but he expects to have the new lab fully equipped in time for harvest 2018.

Araujo and his team are particularly proud of a large technical tasting room that offers plenty of light from large windows that provide a view of the winery’s estate vineyards. Araujo notes Raymond owns the vineyard adjacent to the north and also recently redeveloped it with clean, virus-free vineyard material, and both are Biodynamic.

Kinsman said the technical tasting offers a place for serious sensory analysis, blending trials or hosting members of the trade and media. As it’s totally separate from hospitality, it provides on-site and client winemakers ample room to taste through their wines. “That’s part of the problem when you’re using custom space. Often times it’s just custom-crush space, whereas here you have access to hospitality and to a technical tasting room and lab,” he said. “This is actually the winery that each of our custom-crush clients want or aspire to do.”

Kinsman said the technical tasting offers a place for serious sensory analysis, blending trials or hosting members of the trade and media. As it’s totally separate from hospitality, it provides on-site and client winemakers ample room to taste through their wines. “That’s part of the problem when you’re using custom space. Often times it’s just custom-crush space, whereas here you have access to hospitality and to a technical tasting room and lab,” he said. “This is actually the winery that each of our custom-crush clients want or aspire to do.”

The winery is supplied with water from two plentiful wells, and wastewater is treated with a new Clocina system. Treated winery wastewater is used for landscape and vineyard irrigation. Gray water and sewer is treated with a separate septic system.

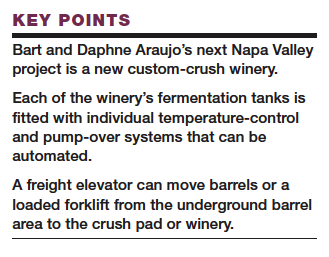

The crush pad is accessible from Zinfandel Lane and provides ample room for forklifts to unload bins from both sides of trucks. Located right next to the crush pad is a cold room that can accommodate stacks of fully loaded half-ton bins. Kinsman said the room is designed to offer cold storage for all the winery clients and can hold a total of 100 half-ton bins, or 50 tons of grapes. He points to the 2011 harvest as an example of a year when everyone was rushing to get their grapes off the vine and into the winery. “We wanted a space where if everyone needed to bring their fruit in in a hurry, we could bring it in, stack it up to the rafters, keep it cool and process it just as quickly as we possibly could.”

The room can be cooled as well as heated if a client needs to restart a stuck fermentation or get some barrels through malolactic. During the rest of the year, the room is used to store the crush pad equipment, which is designed to offer the gentlest and most thorough sorting with the least amount of people.

Precise and gentle processing

Grapes are dumped on a full-ton dosing hopper that feeds a 16-foot-long cluster sorting table. It would be the first stage in the process if the grapes arrived in small yellow bins. Wolf Welding & Fabrication built the hopper and other custom winemaking equipment as well as all the catwalks and other metal fabrication work. The first table empties onto an elevated conveyor that feeds the Bucher Vaslin Delta Oscillys destemmer that shakes the berries free from their stems with a swinging cylinder. The berries then run along another table to a Delta R1 Vistalys optical sorter. The vibratory sorting tables and elevated conveyor are all custom-built Iso-Flo machines by Key Technology.

Donley said the crush pad is set up to be as meticulous, gentle and fast with processing as possible while also reducing the amount of labor needed. With everything up and running, she said the crush pad requires one dedicated forklift driver and another worker to keep an eye on everything, making sure it hums along smoothly at 3.5 tons per hour or slower.

Kinsman said at rates much higher than that, the grapes begin to stack up on each other on the sorting belts, making it harder for the optical sorter to do its job of recognizing grape water berry and other less than ideal fruit.

Araujo said he had resisted investing in an optical sorter for years because he had doubts that a machine could do a comparable (let alone better) job than the skilled sorters who worked at Araujo Estate. For the new winery, however, he conceded to the technology and now admits that the optical sorter does a better job and at a faster rate.

“I have to say it’s truly amazing. The differences in the technology over the decade are extraordinary,” he said. “The bottom line is I never thought anyone or any machine could sort better than our ladies, but this sorts better and three times the speed, so we can process three times as fast.”

After running through the optical sorter, the processed and sorted berries are collected in custom-built stainless steel sumps to transport the must to fermentation tanks. The sumps, also made by Wolff, are moved by a forklift driver who carries them into the winery and then raises the sumps up over the top hatch of the stainless steel fermentation tanks and hits an actuator to open a large butterfly valve powered by compressed air to drain the sump into the tank. “We’re also using these for pressing, so when we’re digging out tanks we’re digging straight into these,” Donley said.

Araujo and Kinsman first saw such bins in action at a winery in Bordeaux and brought the method back to Araujo Estate. The technique replicates gravity feed to some extent and helps reduce the amount of macerated fruit from the transfer process.

All of the 47 stainless steel, double-walled tanks at the winery were produced by Canby, Ore.-based JVNW and range in size from 4 to 7 tons. The winery also has 13 portable tanks for small-lot fermentations or trials in a room separate from the main fermentation area.

Punchdowns or pumpovers

The tanks are set along the northern and southern walls of the winery, and a separate bank of tanks runs down the middle of the winery. Each tank is fitted with its own pumpover system. Punchdown devices by Burgstahler Machine Works run on rails above the tanks along the walls and in the center of the winery. Kinsman said the tank sample valves (often the least clean part of any winery) were custom-built with pharmaceutical-grade steel. The tanks themselves were produced with steel that is nearly pharmaceutical grade, making them easier to clean. “Nothing likes to stick to these like tartrates or anything,” Kinsman said, patting the side of a tank. “Even when they do, you can just whack on the tank and they fall off.”

Araujo concedes the tanks were one of the costlier investments in the winery, but he thinks they were well worth it. Pointing at a pumpover pump, he said, “It just paid off in spades from a quality standpoint, and also the angels’ share is lowered because the wine is not going through the evaporative process of hoses. It’s all in this fully enclosed system.”

Clients can choose to manage their fermentations with either pumpovers or punchdowns. If they prefer pumpovers, a winemaker can schedule them based on length of time, frequency or even by amount of wine. In addition to pump and irrigator, each tank’s pumpover system also includes flowmeters to record how much wine was moved. “We’re here to give the client exactly what they want. This system allows us to do it with very little labor,” Kinsman said.

Clients can choose to manage their fermentations with either pumpovers or punchdowns. If they prefer pumpovers, a winemaker can schedule them based on length of time, frequency or even by amount of wine. In addition to pump and irrigator, each tank’s pumpover system also includes flowmeters to record how much wine was moved. “We’re here to give the client exactly what they want. This system allows us to do it with very little labor,” Kinsman said.

The pumpover system uses Corcoran vortex pumps that pull wine up through a fixed line to the irrigator. Kinsman said just a small amount of wine contacts the impeller, leading to reduced shear. Those pumps can also be connected to a skid with cleaning solution or sanitizer and be used in a clean-in-place system.

“With this closed system, the health of the wine is protected from a microbial standpoint from cross-contamination, and there’s significantly less losses of wine,” Kinsman said.

All of the winemaking operations are run and managed by the VinWizard system, which also monitors and controls the barrel room temperature and humidity. Winemakers can program and monitor winemaking operations via tablets or do it manually. Each irrigator is also fitted with a Venturi to provide fermentations some air if needed. Near every tank are connections for compressed air as well as another gas such as carbon dioxide or argon. If a tank is only partially filled, a winemaker can plug a hose from the gas connect to then regularly gas the headspace via the VinWizard system.

Wine transfers are done with a Waukesha 60 pump from Carlsen & Associates and a Graco diaphragm air pump from Burgstahler Machine Works. Burgstahler also supplied the miscellaneous cellar fittings, sumps and other general winemaking equipment.

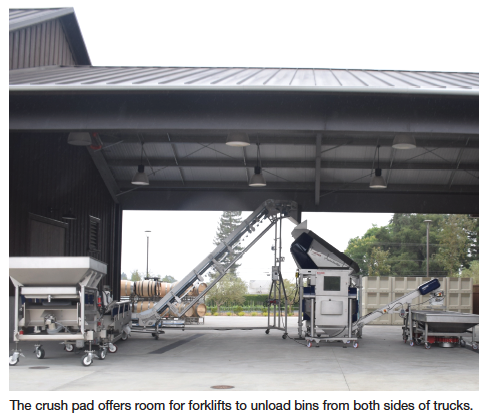

On either end of the central bank of tanks are large-volume Bucher Vaslin presses. A JLB basket press is used for reds, and a XP30 membrane press is for white grapes.

Directly below the winery are two large barrel rooms and a third area that is used for barrel fermentation. Donley said the fermentation area will likely be connected to the winery floor via a fixed line so white juice can flow directly from the press to barrel. In the meantime, barrels are filled at the winery and then taken down to storage with a freight elevator.

The elevator has a capacity of 20,000 pounds and can move a forklift carrying barrels or a portable tank or 20 stacked barrels. At first it seems like an extravagant touch, but Kinsman said it proved cheaper to install an elevator than build a ramp from the surface down to the barrel rooms.

He said a ramp could potentially allow storm water to drain into the cellar, and navigating it could pose a risk for forklift drivers. “We’d have to worry about our staff trying to drive a forklift up a ramp, potentially when it was wet and laden with barrels, so we nixed the concept of the ramp pretty quickly,” he said.

He said a ramp could potentially allow storm water to drain into the cellar, and navigating it could pose a risk for forklift drivers. “We’d have to worry about our staff trying to drive a forklift up a ramp, potentially when it was wet and laden with barrels, so we nixed the concept of the ramp pretty quickly,” he said.

The elevator has doors on both sides so a forklift driver can enter from one side and exit the other, making moving between the barrel cellar and crush pad and winery level nearly seamless.

An open area accessible through two sets of doors provides a space for barrel washing with the winery’s two-barrel Tom Beard unit. While at the same level as the subterranean barrel rooms, the wash-down space is open and allows noise and steam to escape.

Araujo said custom crush typically involves compromises. One may have to delay a pick date because tanks aren’t free, or cut an extended maceration short just to use a press and wait on racking a lot of barrels because one’s stack is at the back of a barrel room. Those compromises can sometimes require a sacrifice in quality, and he did not want any of Wheeler Farms’ clients to have to make that decision. “I wanted to try and walk through those issues and see how many of those we can eliminate to make it as close to having your ow n winery as possible,” he said.

Everything may be new at the old Wheeler Farms, but it also fits Araujo’s style of respecting the origin of a wine. Trying to recreate with the orchard, chickens and gardens a sense of a Napa Valley before it became entirely planted to vineyards is in a way similar to what Araujo wants to do with his family’s new brand Accendo. The wine is a blend of vineyard sources, and Araujo is seeking to bring them together with balance and nuance. “The texture of the wine is extremely important; we want very fine-grain tannins,” he said. “We have to be very respectful of that fruit and do whatever we can to enhance all the qualities from the vineyard.”

Balance and nuance also mean lower alcohol levels for Araujo. He has been tinkering with canopy management—even experimenting with a modified California sprawl to slow the ripening process down. Araujo is looking to make classic Napa Cabernet and now has a modern winery in a historic location to do so.

A space for winemaking and hospitality

A space for winemaking and hospitality

One of the companies making wine at Wheeler Farms is Arrow & Branch winery, which was founded in 2007 by Steve and Seanne Contursi after they purchased a vineyard in the Coombsville AVA of Napa Valley.

Steve Contursi is a successful vintage coin expert, or numismatist, and the owner of Rare Coin Wholesalers and RCW Financial. Contursi owned one of the first silver dollars to be struck in the United States and sold it in 2010 for $7.85 million. The winery’s name relates to the arrows and branches held by the eagle that is found on the “tails” side of most U.S. coins.

Earlier this year, Arrow & Branch, which produces around 1,500 cases per year, moved production and hospitality to Wheeler Farms, and the winery’s staff said the new location has helped both connect with customers and ensure consistent, quality winemaking.

Arrow & Branch wines are produced with grapes from the Contursis’ vineyard that is planted to Cabernet Franc and other top sites such as Beckstoffer Vineyards’ Dr. Crane Vineyard. The wines are made by Jennifer Williams, who was an intern at Araujo Estate and the winemaker at Spottswoode for five years. In addition to Arrow & Branch she produces wine with her husband under the Zeitgeist Cellars label. She said she likes that Wheeler Farms is a serious, practical winery where the aesthetics have not trumped the functionality of the facility. “The focus is really on making high-quality wines,” she said.

Williams said Arrow & Branch wants to produce wines that reflect the vineyards from which they came, so she likes that the winery has a large cold room to keep grapes at ideal temperature and give her the flexibility to react to vintage conditions. She also likes that Arrow & Branch has its own dedicated tanks and that fermentations in those can be managed through punchdowns or pumpovers.

Williams described herself as a hands-on winemaker who likes to taste and see a wine progress through fermentation, but said she likes how Wheeler Farms’ equipment enables her to retain manual control while keeping automated programs as an option.

More control and the crush pad equipment also allow Williams to do as little as possible to the grapes and that, she said, is the best way to ensure a pure expression of the vineyard. “I really like what we’re trying to do: make hand-crafted wines that are really representing vineyard sites,” she said.

On the hospitality side, general manager Elizabeth Robertis said the winery’s hospitality area offers the right mix of openness and privacy that works well for connecting with consumers willing to pay the tasting fee of $125 to taste through Arrow & Branch’s Sauvignon Blanc, two Cabernet Sauvignons and a Cabernet Franc-based Bordeaux blend.

Robertis can set up tastings in several areas including a private room and outside on a patio with a view of the estate vineyards and Mount St. Helena. She said the hospitality area can accommodate two parties at once while still retaining a private feel. Arrow & Branch and the other client wineries at Wheeler Farms use a shared calendar so they don’t book conflicting appointments.

She added that the winery is also in an ideal location—almost literally in the center of Napa Valley—so visitors can add it to almost any Napa Valley winery visit itinerary. “We’re really excited to be part of it,” Robertis said of the new winery.

Araujo said the tasting area is meant to feel like a home, yet it still offers plenty of areas for private, exclusive experiences that visitors to Napa expect. He added he purposely kept it lightly furnished so the hospitality staff of the various client wineries and his own team could figure out how best to use the space. The room hosted a large dinner during the Auction Napa Valley weekend, and Araujo was quite happy to see guests walking around, enjoying the patio and making full use of the inviting and open design.

Because he secured an existing permit from several years ago, Araujo can host more events than other new wineries in Napa Valley, and he expects to make full use of the commercial kitchen as well as the vegetable garden and orchard on the property to entertain and provide visitors with something more than just a wine tasting. “My idea is that when you taste wine, it will be in conjunction with the bounty of the property, so there will be pairings with what we’ll be able to grow here,” he said.

“What was Napa Valley like back when Wheeler Farms wasn’t all vineyards? The new consumer is all about experiences, so we want to try and give them as honest and authentic a type of Napa Valley agricultural experience as we can.”

|

|

PRINT » |

|

|

E-MAIL THIS ARTICLE » |

|

|

CLOSE THIS WINDOW » |