Growing & Winemaking

by Patrick L. ShabamGrowing & Winemaking

January 2019The Limitations of the Winkler Index

The Winkler Index or Winkler Scale is a standard for describing regional climates for viticulture in the United States. Developed by A.J. Winkler and M.A. Amerine at the University of Cali-fornia, Davis in the first half of the 20th century, the index was constructed to corre¬late wine quality with climate, focusing on California viticulture. Wine-producing regions of California were broken into five climatic regions using heat summations above 50° F, or growing degree days (GDD). Heat summa¬tions are a way of looking at accumulated temperatures over a given time period. De¬spite the common usage of the Winkler Index, the classifications offer greater uncertainty than the system suggests.

An obvious drawback to the Winkler Index is the focus on temperature alone. Winkler’s groundbreaking resource “General Viticulture” notes the influence of “rainfall, fog, humidity and duration of sunshine,” but Amerine and Winkler’s work and subsequent research found that temperature plays the greatest role in the development of wine grapes. As the focus of Winkler and Amerine’s wine-grape research was on California viticulture, their climatic regions had the luxury of ignoring precipita¬tion, as little rain falls during the growing season. Indeed, Winkler et al. in “General Vi¬ticulture” suggest that the vinifera grape “is not suited to humid summers, owing to its suscep¬tibility to certain fungus diseases and insect pests that flourish under humid conditions.”

Advances in viticulture have expanded the range of successful commercial vinifera pro¬duction, while more recent research notes the importance of wind on photosynthesis rates. Winkler et. al. also point out the importance of ongoing refinement of local variations, stat¬ing, “It is hoped that refinements will be de¬veloped so as to delimit subregions within the present regions, thereby ensuring the greatest potential for quality when the most favorable climatic subregion for a given variety is planted to that variety.”

Therefore, the Winkler Index was designed at a state scale, and not necessarily intended for smaller viticultural subregions or single vineyards.

READ MORE »

Growing & Winemaking

January 2019Reflections from a 50-year Vineyard Meander

I was flattered when I was invited to contribute to the final issue of Wines & Vines, commemorating 100 years of distinguished service to the American grape and wine sector. As an older member of the viticultural science fraternity, I have seen many changes in my 53 years working in vineyards, and I will comment on some of these here. I have been involved in research, teaching and consulting in more than 35 countries and many wine regions of the world, so I can offer some sort of international perspective.

A vital element of a successful grape and wine industry is communication between members, especially of technical information. To go back 50 years, this was largely the pur¬pose of trade magazines such as Wines & Vines. I recall that when I began my career, I was a devout reader of the Australian equivalent. Now trade meetings are more fre¬quent, and there are many other sources of information, but the printed word still has an important place. Trade magazines remain an important information source, and most grape and wine scientists still use them to get their message out to in¬dustry practitioners.

Another important American legacy is the American Society for Enology and Viticulture, which has spawned similar societies in Australia, South Africa, New Zealand and Japan. Well done, ASEV.

While I was born in Australia and spent much of my life there, I have been a frequent visitor to the United States over my profes¬sional career, for education, speaking engagements and con-sulting. I have visited most grapegrowing states of the U.S. To my mind, the United States and Australia have been im¬portant countries so far as technical improvements in viticulture have been con¬cerned, some of which I ac¬knowledge here.

I wondered about a relevant approach to this historical review and decided on a classification of “what had changed” in this period from 1966 to 2016, and “what has not changed,” some of which maybe should have! After I wrote this column, I came across Cliff Ohmart’s colum in the August 2018 issue of Wines & Vines, “Twenty years of sustainable winegrowing,” where he took a similar ap¬proach. Some of our conclusions are similar.

I wonder if there may be another period of 50 years with more changes than have occurred over the period of, say, 1966 to 2016, which I am discussing. I am no historian, and maybe others will comment, but it seems to me this has been a period of very substantial change. The following entries are listed in no particular order, but I would hope that some of the more significant from a global point of view are included higher up on the list.

Irrigation

READ MORE »

Growing & Winemaking

January 2019Grapegrowing Interview: Jordan Wente and Nikki Wente

For this Collector’s Edition of Wines & Vines, we thought that a youthful perspective from family members of the oldest continuously operated family-owned winery in the United States would be appropriate. Sisters Jordan Wente and Niki Wente are the youngest family members now involved in running Wente Family Es¬tates, a 750,000-case winery and dining, golfing and concert destination founded in California’s Livermore Valley in 1883.

Jordan, whose title is fifth-generation winegrower and project manager, procurement, joined the business in 2015 and has worked in project management and supply-chain roles. Currently she supports ongoing custom- and private-label projects. She earned a B.A. in political science from the University of Colorado, Boulder, and an MBA from California Polytechnic State Univer-sity (Cal Poly) in San Luis Obispo.

Niki, whose business card says fifth-generation winegrower and viticulture supervisor, joined the business in 2017 and now manages the buy¬ing and selling of grapes and winegrower rela-tions. Niki graduated from Cal Poly in June 2014 with a B.S. in wine and viticulture. One of her interim jobs was a role in grower relations and viticulture at Napa-based Huneeus Vintners.

Both are daughters of Phil Wente, who with his sib¬lings Carolyn Wente and Eric Wente are the senior members of the family ownership structure. Jordan and Niki are first cousins of Karl Wente and Christine Wente, who have been involved with the family business for about 15 years. The sisters sat for the interview at the Wente winery on Tesla Road in Livermore on Oct. 15, 2018, when their grape harvest was about 40% finished.

Q: What’s it like to be the youngest family members working at a 135-year-old family winery? Do you feel pressure?

Jordan Wente: Really there is not a lot of pressure on us. Our family has always shared so much and developed us so much that it’s a really comforting feeling to have that support. You never feel like you are under a ton of pressure, or at least I don’t. Because I know that they’re there to coach me and to teach me and grow me and support me.

Niki Wente: For me, I think that it is a lot of pressure. I’ve worked at other businesses in the wine industry, and coming back here I feel a lot of pressure that I really want to perform well, and I want to make this a wonderful place to work for everyone around me as well as kind of continue to move forward in this industry. But we have such a good support system. I call my dad almost daily and can talk to him about any issue we’re going through in the vineyards. He’s there to listen and talk me through it. It’s never an overwhelming pressure. It’s more of an exciting thing, because I’m excited to come to work every day. I want to see us succeed. I want to see my kids have the op¬portunity or option to come here and work.

READ MORE »

Growing & Winemaking

November 2018Domestic Sparkling Wine Finds Its Identity

While many in the wine trade consider Champagne the “king of wines and wine of kings,” more consumers increasingly regard sparkling wine as its equally regal offspring.

READ MORE »

Growing & Winemaking

August 2018A Conversation with Joe Dobbes

Winemaker Joe Dobbes grew up on a farm in Oregon's Willamette Valley, where he raised marionberries, a type of blackberry. His father, a doctor, was also a home winemaker, and young Joe liked to spend his time in the kitchen, developing his interest in diverse flavors.

READ MORE »

Growing & Winemaking

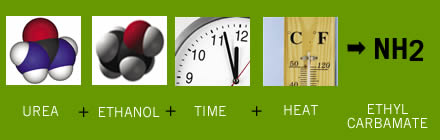

June 2018Cold Stabilization and Malolactic Fermentation

Two products that could help winemakers produce significantly better wines should prompt wineries to seek approval from the Alcohol and Tobacco Tax and Trade Bureau (TTB), which has not fast-tracked these items.

The first is Zenith, a colloidal material that will cold-stabilize both white and red wines permanently. Enartis developed the product and introduced it at this year's Unified Wine & Grape Symposium.

The second is a bacteria, Lactobacillus plantarum, that can consume malic acid to finish malolactic fermentation (MLF) more quickly and completely and with fewer side metabolites. L. planetarium is approved internationally for use in wine and in the United States for beer, but not for wine.

Zenith Uno and Zenith Color

READ MORE »

Growing & Winemaking

June 2018Producing Cabernet Wines at Different Price Points

Cabernet Sauvignon is the most popular red varietal wine with consumers and critics and the grape is expected to soon surpass Chardonnay as California's leading wine grape variety by tonnage and acreage.

In light of the varietal's dominance, four different Cabernet wines at four different price points were dissected in a tasting and panel discussion at the Unified Wine & Grape Symposium earlier this year. The session included presentations by the vineyard manager and winemaker responsible for four wines.

Moderating the session was Chris Munsell, director of winemaking for E. & J. Gallo Winery's premium wine program. Munsell said when he "was a wee lad in the winemaking world" a marketing executive told him for any wine to be successful it needed to be of good quality, known by consumers and profitable for everyone involved.

He said no other varietal or red blend has received as many 100-point scores as Cabernet Sauvignon and its popularity and profitability are obvious by the grape's place in the wine industry. When Munsell was introducing the panel he said he would not be surprised if Cab had outpaced Chardonnay in terms of total

production in the 2017 vintage, but when the California crush report came out about a month later, Chardonnay had held on to its top spot, barely. Growers harvested 614,565 tons of Chardonnay and 601,473 tons of Cabernet. Both varieties had a 14% share of the state's total wine grape harvest.

"Cabernet Sauvignon is also in a unique position where you see wines from from 7 to 8 bucks a bottle all the way up to 700 or 800 bucks a bottle and everything in between. Very few other varietals have that scope," Munsell said.

At $13 consistency is key

READ MORE »

Growing & Winemaking

May 2018How Wineries Take Advantage of Big Data (or Any Data)

Are the winemaking and sales decisions in your winery data-driven? Are all of your data sources well integrated into one system? Ask the question of some winery owners, and you may get these responses:

• "I will use data to run my winery once a really well-known Napa Valley winemaker does it and gets a98-point score. It's the wine industry, where everyone strives to be the first one to be the second one."

•"My winery prides itself on making wine exactly the way they did in France in the 18th century. I evenhave my tasting room staff wear Les Miserables costumes at work, and on weekends when we have bigcrowds, I make them sell their teeth just like Fantine did. The tourists love it!"

• "Data analysis is what the 'big guys' do, but not here. We're just farmers."

• "Wine is an art."

True, I invented the quotations above, but they're not as far-fetched as you might think. Data is generated at every step in the winemaking process, from soil moisture to vineyard sampling to weight tags to all steps of winemaking to case goods to sales to consumer data. We are buried in data, yet we often make important decisions on anecdotes and "gut instinct." Everyone has a story of an owner saying more or less, "I love our Gold Digger's Reserve, named after my last three wives. Sure, we only sell 173 cases every year, but let's keep making 1,000 cases."

Marshall Graves is a vice president and wine industry specialist at Bank of Marin. He encourages wineries to "go beyond using your data set to simply resell to existing customers. Aggregate and examine your data to obtain a precise understanding of what your club members enjoy beyond wine."

Graves suggests accomplishing this by collaborating with companies that specialize in data analytics and social physics. "Done well, this will improve wine club retention and ultimately result in wineries having a more efficient and cost-effective marketing strategy." He added that "each of the top five wine-producing states also have established technology hubs. Those who engage in conversation with their tech community will become agents of change vs. being the disrupted."

We all know we need to use data better, but turning it into something that objectively drives decision-making is a challenge for nearly everyone. I interviewed representatives of two wineries and their data vendors who are successfully integrating and using data in their everyday operations.

DRY CREEK VINEYARD

READ MORE »

Growing & Winemaking

April 2018Seeking Perfection in Pinot Noir

If the devil is in the details, then Pinot Noir makers comprise an unholy lot. Pinot Noir cuts a cruel swath through winemakers who may be inattentive, ill-informed or uninspired.

READ MORE »

Growing & Winemaking

March 2018A Conversation With Randy Heinzen

Andy Heinzen set out to become a computer engineer when he enrolled at California Polytechnic State University in San Luis Obispo. But the Gilroy native, whose family had farmed in California’s Salinas Valley for generations, realized that he would never leave his cubicle with that degree. So, he switched to political science, with an eye toward advocacy for the wine industry. When Cal Poly added a minor in enology and viticulture, he signed on to that program, too, graduating in 2000.

READ MORE »

Growing & Winemaking

February 2018How Semillon Grapes Adapt to Botrytis

Every year, winemaker Greg Allen waits as Napa Valley Sémillon takes its sweet time to mature. His staff and a team of researchers from the University of California, Davis, have demonstrated that grapes from John’s Creek vineyard are as hard at work in early November as the Far Niente field crew gearing up for late harvest.

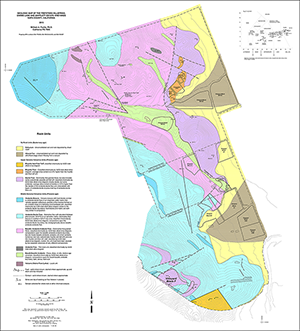

Part of the 11,000-acre Coombsville sub-AVA, the 17-acre vineyard straddles some of what’s left of a volcanic vent that collapsed under its own weight 5 million years ago. The crescent-shaped caldera borders the Napa River to the west, the Vaca Range to the east and Mount George to the north.

Warm air rising from the valley floor draws coastal fog off the San Pablo Bay, moderating daytime temperatures and fueling a seemingly endless summer of misty mornings, warm days and moist nights. A temperate autumn extends the vintage, lengthening hang time and delaying harvest.

The valley’s maritime climate, hillsides that block the wind and trap humidity, and well-drained, nutrient-poor soil make the grapes ripe for Botrytis cinerea. Unlike bunch rot, which saps life from vines under a swath of moist mid-summer air, noble rot enhances the aromas, color, flavors and texture of wine made from late-harvest grapes, such as Far Niente Dolce.

By late fall, the grapes have ripened. Botrytis, a fungus that overwinters in the soil and on the vine, has drained moisture and nutrients from the infected berries and is rewriting the sensory profile of Sémillon grapes.

“Noble rot reprograms berry development and metabolism,” says Dario Cantu, plant geneticist and professor from the Department of Viticulture and Enology at UC Davis. “The interaction of the fruit and fungus stimulates metabolic pathways otherwise inactive in white-skinned berries, leading to the accumulation of additional compounds and creating the unique flavor and aroma of botrytized wines.”

When conditions are right—still air, high humidity, light rain and air temperatures that range from 58° to 82° F—the velvety gray fungus penetrates cracks in the cuticle of the grape, softening and dehydrating the berry. Threadlike hyphae trigger the nuclei of host cells to express genetic traits that redefine the sensory attributes for late-harvest wine. The sugar, acid and trace minerals that the mold leaves behind help define its character.

Sweet idleness

READ MORE »

Growing & Winemaking

January 2018How to Prepare for the Next Disaster

There is little to add to the reporting about the firestorm that struck Mendocino, Napa and Sonoma wine country Oct. 8, 2017. It was unlike any other disaster to hit California. Within a few hours, 21 separate fires started, whipped by 50- to 70-mile-per-hour winds that increased in velocity as the conflagration quickly grew. From CalFire we learned that the Tubbs Fire burned more than 5,300 structures, making it California’s most destructive wildfire ever. The 1991 Oakland Hills fire is a distant second at 2,900 structures lost. Three additional fires started that night are among the 20 most destructive blazes in California history: the Nuns Fire (No. 6), Atlas Fire (No. 10) and Redwood Valley Complex (No. 16).

READ MORE »

Growing & Winemaking

January 2018Fruit Flies Play Role in Sour Rot Complex

Sour rot is a term that is widely and somewhat inexactly used to refer to a group of late-season bunch rots that are particularly problematic on tight-cluster or thin-skin grape varieties. In California, it is another name given to a complex of fungal species and other microorganisms often referred to as summer bunch rot, which is reported to begin attacking berries when they reach a maturity stage corresponding to 8° Brix.

READ MORE »

Growing & Winemaking

January 2018A Conversation with Josh Jensen

World-class Pinot Noir from California seemed an improbable goal back in 1975, when Josh Jensen planted his first vineyards at Calera Wine Co. Jensen, a California native, had spent a couple of harvests in Burgundy in the early 1970s, and the place and its wines were a revelation to him.

READ MORE »

Growing & Winemaking

January 2018Tooth Care for Wine Professionals

Tasting the fruits of one’s labor is one of most rewarding parts of being a grapegrower or winemaker. However, it can also be an occupational hazard, with a greater predisposition among winemakers and wine judges to experience premature gum recession (from harsh tooth brushing), tooth erosion, tooth sensitivity and dry mouth due to greater and more frequent exposure to the acids present in wine. This article addresses some of the dental issues relevant to wine industry personnel as well as preventative measures that should be taken when tasting large numbers of wines in situations such as wine shows.

READ MORE »

Growing & Winemaking

January 2018Traminette's Popularity Spreads Across the East

Traminette, an aromatic grape related to Gewürztraminer, has become a popular variety in 19 states. First named in 1996 by the New York State Agricultural Experiment Station (NYSAES), the variety has experienced widespread growth from the East Coast to as far west as Missouri. It is very popular in New York’s Finger Lakes region and has been named Indiana’s “signature grape variety.” In addition, it was named Outstanding Fruit Cultivar by the American Society for Horticultural Science in 2015, the fourth NYSAES-bred fruit cultivar and the first grape to be so honored. Much of Traminette’s background information presented here was provided by Dr. Bruce Reisch at Cornell University and Dr. Bruce Bordelon at Purdue University.

READ MORE »

Growing & Winemaking

December 2017Future Farm Expo: Agriculture Interconnected

This August, I was fortunate to attend the Future Farm Expo in Pendleton, Ore. Following the theme of “Agriculture Interconnected,” there were speaker sessions focused on field robotics and automation, ground sensors, crop imagery, data use, precision irrigation and more.

The expo addresses the fundamental issue that farms must significantly improve productivity if the Earth is going to be able to feed 2 billion more people by 2050. At the same time, physically demanding and/or dangerous jobs are being eliminated. Grape presses were once hand-cranked, which is fine if you don’t mind hiring (and probably having to feed) a number of beefy employees and can live with leaving 25% of the juice behind. Coal mining is no longer done with a pick and shovel; instead, entire mountaintops are removed with explosives and massive pieces of equipment—a safer (though environmentally disastrous) and more efficient method that requires very few employees.

Beyond the global picture, the grape industry faces these challenges:

READ MORE »

Growing & Winemaking

December 2017Probing Nutrient Needs of Pinot Noir Vines

Seasonal uptake from the soil and use of nitrogen in grapevines has been examined in studies from numerous grapegrowing regions.1-3, 5-11 Uptake of other macronutrients including phosphorus, potassium, calcium and magnesium has received less attention,4,9,11 and no published study has determined the timing or quantities of micronutrient uptake of manganese, boron, zinc or copper for field-grown grapevines.

The majority of total seasonal nutrient uptake from vineyard soils (mainly for nitrogen) has been reported to occur between bloom and véraison in most studies on wine grapes (Vitis vinifera) and Concord grapes (Vitis labrusca) coincident with the increase in total vine biomass.2,3,5,6,7,9 However, some studies of wine grapes have found greater nitrogen uptake from vineyard soils between bud break and bloom than between bloom and véraison,1,8,11 even though the bulk of total vine biomass increase still occurred between bloom and véraison.

The majority of phosphorus uptake occurred early in the growing season (close to the time of flowering) in Pinot Noir,11 while the uptake for potassium, calcium and magnesium has mostly been reported between bloom and véraison.4,9,11

Given the differences observed in nutrient uptake of whole vines from previous trials, the nutrient uptake of young Pinot Noir vines was studied to provide growers with better information about the nutrient needs of young vines and when nutrient uptake occurs to provide better guidelines to manage nutrient inputs for young vineyards.

Key finding: Nutrient uptake and remobilization varies by specific nutrient

READ MORE »

Growing & Winemaking

December 2017How I Learned to Stop Worrying and Love the Drone

I recently acquired a new hammer, in the form of an aerial drone, and have been using it to hover over vineyards to look for nails. I have found many “nails” in the process.

I, drone: Separation of concerns

READ MORE »

Growing & Winemaking

November 2017A Conversation with Aron Weinkauf

Spottswoode Estate in St. Helena, Calif., is a Napa Valley classic: Wine grapes were first planted there in 1882. The current estate was established by Jack Novak and his wife, Mary, who started out as grapegrowers. Following her husband’s death, Mary Novak (who died last year) founded the current winery, 100 years after grapes had first been planted there. The collection of buildings dating from the 1880s exude a sense of history.

Spottswoode celebrates tradition, but it has not been bound by it. The winery has been an innovator over the years. The Novak family has farmed the estate vineyard organically since 1985, and it was certified in 1992. More recently, Biodynamic practices have been introduced. The winery recently has been renovated, and state-of-the-art equipment has been added.

Supervising both vineyard and winemaking is Aron Weinkauf, who has been with Spottswoode since 2006, when he became assistant winemaker under Jennifer Williams. Weinkauf, who graduated in 1999 from Berry College in Georgia with a degree in Spanish, developed an appreciation for wine while studying in Spain. When he returned to the states, Weinkauf enrolled in the viticulture and enology program at California State University, Fresno, and graduated in 2005. He worked at Ficklin Vineyards and Paul Hobbs before joining Spottswoode.

Weinkauf developed a deeper interest in viticulture at Spottswoode, and he became vineyard manager (in addition to his winemaking duties) in 2009. Two years later, he became the fifth head winemaker in Spotts-woode’s history.

Q: You’ve been using an optical sorter for several years. What are the advantages? Has it improved quality? Are there any disadvantages to using it?

READ MORE »

Growing & Winemaking

October 2017What Bottle Weight and Label Copy Convey

If it seems like the use of heavy bottles is increasing, that’s because it’s true. Rich DuBois, product manager for M.A. Silva and one of the industry’s most knowledgeable packaging professionals, told me just that. During the recession in 2010-11, the use of eco-friendly lightweight bottles (those weighing 450 grams or less at 750 ml capacity) peaked. Since then, the use of heavier glass (600 grams or more) has increased. Wineries that have moved to heavier glass are staying with it, because it’s working for them.

To categorize glass by weight and cost, DuBois gives this guidance:

READ MORE »

Growing & Winemaking

October 2017Best Practices for Gas Management at Bottling

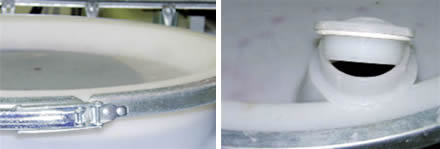

Total package oxygen (TPO) management at bottling is crucial to avoid wine oxidation. According to bottling audits performed around the world, average TPO is 3 parts per million (ppm). This one-shot addition of 3 ppm at bottling may seem rather small, but when compared to what a closure brings per year—1 mg of oxygen in the case of a Nomacorc Select Green 100, for example—this potentially corresponds to three years of shelf life. It is important to take good care of TPO and develop strategies to control it in a consistent manner across the bottling process.

Both dissolved oxygen (DO) in the wine and headspace oxygen (a function of oxygen percentage in the headspace and headspace volume), when combined, are the definition of TPO.

How can low TPO be achieved? A key point is to measure O2 regularly at different bottling steps. Measuring TPO regularly is the only way to accurately quantify critical oxygen pickup and identify TPO variations during the process. The most recognized way to measure it is to use the NomaSense O2 P300 analyzer and a piercing system designed to facilitate real-time TPO measurements.

Based on hundreds of bottling audits performed around the world, we developed a specific quality-control approach both on gas-management and bottling-line settings in order to help wineries achieve best-in-class bottling practices.

Start with a low dissolved oxygen concentration in wine

READ MORE »

Growing & Winemaking

October 2017Regional Typicity of Cool-Climate Rieslings

The word Typicity is guaranteed to start animated discussion among sommeliers, wine educators and beverage directors alike. It is commonly used as a positive attribute when discussing varietal or regional wines, but it’s difficult to reach a consensus over how typicity is defined or achieved. Is typicity reflective of that other troublesome wine word, terroir? Differences exist between a Riesling produced in the Finger Lakes (FLX) AVA and one produced in Alsace, but what these differences are and who is qualified to evaluate them seems to change each time the question is posed.

While typicity and terroir are important concepts in wine quality, they have been hotly debated and poorly defined since the beginning of wine evaluation. The French designation Appellation d’Origine Contrôlée guarantees the quality of wine produced in a specific region, with sensory and chemical markers reflecting its geographical environment. This AOC designation, along with winemaking practices, are believed to generate a product that is typical, or representative, of its terroir.1

Though there has been a recent shift in the sensory community to make wine evaluation more objective, variations in wine-production methods, vineyard conditions and wine evaluators produce mixed results in studies seeking to tie aspects of terroir with typicity. In a 2009 study, Lucie Perrin and Jerome Pagès concluded that appellation alone was not sufficient to determine the sensory attributes of a wine from a specific appellation, due to high variability between wines of the same region. When Perrin and Pagès took these wines and compared them on the global scale, however, using the Napping method, the results were closely correlated with appellation.2

Studies in Burgundy headed by Le Fur3 and Ballester4 reframed the contrast of wine origin and wine typicity by comparing product space (e.g., Chardonnay wines from Burgundy) with sensory space (i.e., wines that experts felt typified Burgundian Chardonnays). With these two examples, sensory space and product space have a lot of overlap but are not identical. In Le Fur’s experiment, for example, Burgundian Chenin Blanc and Melon de Bourgogne were often ranked as “very typical” of Burgundian Chardonnay, and shared sensory space but not product space. Such overlap is expected in any exploration of regional wine typicity and can be used to help define expert and consumer perceptions of “typical” wines.

In the Finger Lakes region of New York, Riesling is unquestionably king, and regional experts of all sorts—producers, retailers and die-hard local fans—all can tell you what a “typical” FLX Riesling is. Dry, with notes of apricot and lime zest? Semi-sweet, with luscious fruit? There’s not necessarily agreement among local experts, which is problematic when the industry poised to send a flagship product out into the global market.

Typicity is generally defined by groups of experts who come to agreement over years of tasting. If the local experts don’t do it, typicity will be imposed by writers, sommeliers and tastemakers from the broader wine world. This raises several questions: Can an emerging wine region shape public notion of their own typicity? Should they? And do “experts” even experience wine the same way that their regular customers do?

Sensory evaluation study at Cornell

READ MORE »

Growing & Winemaking

September 2017Evolving Styles for Marquette Wines

To oak or not to oak? That is the question facing many Marquette producers as the promising cold-climate grape comes of age. While vintners initially relied heavily on traditional oak treatments for red wine in general and hybrids in particular, many of them have found that less is more. Hybrid barrels, oak staves and oak spirals have become much more widely utilized.

With few exceptions, winemakers across the northern tier of states have moved toward letting the grape, first released in 2006, express its own particular style and attributes. Even one of the grape’s progenitors has curbed his oak program for Marquette.

“We have been evolving at Saint Croix (Vineyards in Stillwater, Minn.),” said Peter Hemstad, who helped develop the grape at the University of Minnesota and has been making Marquette longer than anyone. “We traditionally have made it in a heavy style, pretty extracted and pretty heavily oaked in barrels for more than a year. In recent years, we decided to dial it back a little.

“Even if you make it with no oak, it’s an appealing wine with complexity. I think oak complements it, and I also think the marketplace now appreciates a little less oak than we made it with originally,” he added.

After using American oak for years, Hemstad and his winemaker, Martin Polognioli, now use a mix of new, one-year-old and two-year-old hybrid barrels with French heads and American staves. They’re sourced from two Napa-based outfits—primarily World Cooperage with a few from Seguin Moreau.

At Lincoln Peak Vineyard in New Haven, Vt., Chris Granstrom has followed a similar path but moved even further away from new oak. He started off using new American oak barrels. “If you’re a new winery, you get a lot of new barrels,” he said with a chuckle. He now employs mostly “a French-American hybrid barrel with a few years on it,” with about 15% new hybrid barrels from World Cooperage.

At February’s Cold Climate Grape Conference, Granstrom told a gathering, “I’m not sure that the right amount of oak for Marquette is zero, but it’s pretty close to zero.” In a recent phone interview, he elaborated: “The only reason I can say that is that I’ve tasted a lot of Marquette, and a lot of it is over-oaked.

“Marquette has a lot of flavor, and a spicy thing going on. But for whatever reason, all that uniqueness gets squelched (by new oak), and it tastes like just another oaky red wine,” he said. “I think it’s especially prone to too much American oak, because the vanilla really dominates Marquette.”

Whatever Granstrom is doing is working: Lincoln Peak’s Marquettes have won a raft of gold medals at competitions as well as a Best in Show for Red Wines award for its 2013 Marquette at the 2015 International Cold Climate Wine Competition.

Other oak sources

READ MORE »

Growing & Winemaking

September 2017Winemaker Interview: A Conversation with The Corley Family

Chris (from left), Stephen, Kevin and Kent Corley all handle different aspects of their family-owned wine business.

Chris (from left), Stephen, Kevin and Kent Corley all handle different aspects of their family-owned wine business.When Jay Corley was studying for his master of business administration degree at Pepperdine University in Malibu, Calif., his thesis was about starting a vineyard and winery business. After spending a few years on successful business ventures in Southern California, he decided to put that thesis into practice.

READ MORE »

Growing & Winemaking

August 2017How Wineries Choose Their Closures

In 1999, two major synthetic cork brands were launched using a new extrusion technology that is still the standard in the industry. After 18 years, synthetics have roughly 20% of the wine bottle closure market. Screwcaps, too, are estimated to have as much as 20% market share, while other alternatives such as technical corks that combine fine cork particles, microspheres and glue are growing steadily as well. Alternative packages such as cans, kegs and bag-in-box also are growing. For the wine industry, this much change in 18 only years is considered “disruptive technology.”

By comparison, other industries innovate just a little more rapidly. In 1999, Dell Computer launched its top-of-the-line Latitude R400GT notebook computer featuring a battery life of two hours, 64 MB RAM, 6.4 GB hard drive, a CD-ROM drive, and weighing only 7.4 pounds for $3,098. Today, we can buy a much faster, lighter laptop with a better screen for about $600.

In 2017, we know all the wine closures I mentioned are commercially and technically acceptable. We also know that wineries have their preferences and opinions, which are based on their own experiences.

I interviewed five wine industry decision makers—winemakers, winery owners and a marketing manager—from coast to coast to learn why they use what they use to seal wine bottles. The five wineries represented make wines in a wide cross-section of styles, price points and locations, and target them to vastly different consumer groups.

Closure certainty for luxury wines

READ MORE »

Growing & Winemaking

July 2017A Conversation with Scott McLeod

Winemaker Scott McLeod, a native of Marin County, Calif., got interested in fermentation when he tried his hand at making beer while he was in high school. That interest took him to the University of California, Davis, where he graduated in 1985 with a degree in fermentation science.

While he was studying at Davis, McLeod spent a year at Isole e Olena in Chianti Classico, and he returned to the Italian wine region after graduation to work for another year at Badia a Passignano. When he returned to California, he bounced around the Napa Valley, working for several wineries, until winemaker Tony Soter introduced him to Francis Ford Coppola. Coppola hired McLeod in 1991 to make the wines at his Napa Valley estate, then known as Niebaum-Coppola. As director of winemaking, McLeod made the estate wines, including the flagship Rubicon Estate red, and oversaw wines such as the Diamond Series bottlings.

After 18 years working for Coppola, McLeod struck out on his own in May 2010. He’s a partner in WineXRay and Safe Harbor Wine Storage, both in Napa. He’s also the winemaker for George Lucas’ Skywalker Vineyard in Marin County as well as consulting winemaker for Daou Vineyards and Parrish Family in Paso Robles and Monte Xanic in Mexico’s Guadalupe Valley. McLeod also consults for several other winery and vineyard projects and is a partner in 180 acres of vineyards in El Dorado and Monterey counties.

QOne of your ventures is an analytical service in Napa called WineXRay. Please explain what sort of analysis you provide.

READ MORE »

Growing & Winemaking

June 2017Self-Assessment Workbooks: Where Are They Now?

It has been 20 years since the first self-assessment workbook about the sustainable production of wine grapes was published in the United States. Since then, self-assessment workbooks have been written for and used by wine grape growers in California, Washington and New York, and by juice grape growers in New York, Michigan and Pennsylvania. Their use has had a significant influence on sustainable winegrowing programs, practice implementation and sustainability reporting. No other U.S. agriculture sector has adopted the use of self-assessment as much as the wine and grape industry. Because of the workbooks’ widespread use and influence, I thought it would be interesting to contact the various programs using self-assessment workbooks to find out if use has changed over time and, if so, how.

But first, for those readers not familiar with self-assessment workbooks, they consist of a list of farming practices that a grapegrower reads and uses to record whether or not they are using the various practices. They can be used for reasons such as in education and outreach programs, encouraging growers to increase wine grape quality, stimulating them to continually improve, enabling groups to anonymously aggregate assessment results for use in sustainability reporting, benchmarking practice implementation and measuring wine grape-growing improvement over time. A great attribute they all share is that any and all growers can use them since they incorporate a broad range of wine grape-growing practices.

Beginning in the Central Coast

READ MORE »

Growing & Winemaking

May 2017Vineyard Management Following a Wet Winter

We are all delighted it finally has rained enough in most of California to end drought conditions. It was a long five years. In many regions, rainfall is 50% to 75% above average. Snowpack in the Sierra was 175% to 200% above normal by late March. On my property along the upper Russian River in Mendocino County, we had five flood events—a record in my lifetime! Most reservoirs are full around the state.

While we all enjoy having water again, the abundant rainfall can cause some profound effects in your vineyard.

Flooded areas

READ MORE »

Growing & Winemaking

May 2017Heading Toward the 'No-Touch' Vineyard

In a decade or less, a vineyard owner could “farm” by sitting in front of a monitor or, more likely, a smartphone or tablet.

Unmanned aerial vehicles, self-driving tractors with robotic implements and elaborate real-time monitoring systems could eliminate the need for human labor and turn into a reality the concept of the “no-touch” vineyard.

While it’s debatable when such a future will arrive, as agricultural labor continues to grow more scarce and more expensive, it’s undoubtable that more and more vineyard operations will be mechanized and eventually automated. The subject was the focus of lengthy sessions at this year’s Unified Wine & Grape Symposium in Sacramento, Calif., and the WiVi conference hosted in Paso Robles, Calif., by Wine Business Monthly. (Both Wine Business Monthly and Wines & Vines magazine are part of Wine Communications Group.)

The panel at Unified focused more on high-tonnage vineyards, but at WiVi vineyard managers for Jackson Family Wines and Treasury Wine Estates discussed how they’ve mechanized premium vineyard operations as well.

Speakers on both panels said there’s a need for more mechanization but stressed it isn’t yet a one-size-fits-all solution that can easily be brought to just any vineyard. “I truly do feel that what we talk about here today, we’re moving in the right direction,” Aaron Lange, the vice president of vineyard operations for LangeTwins Family Winery and Vineyards, which owns more than 7,000 acres of vineyards in the Lodi, Calif., area, said during Unified. “We will absolutely have a no-touch vineyard in five or 10 years. I truly believe it.”

A shrinking, aging labor pool

READ MORE »

Growing & Winemaking

April 2017Benefits of Egg-Shaped Wine Tanks

One of the latest trends in winemaking equipment involves the egg-shaped wine tanks that have found their way into many wineries. There is a great deal of myth surrounding the utility and functionality of these vessels. Since I used an egg tank last harvest, I decided to review the literature about how these tanks are being used and what a winemaker might expect if venturing into this “new” esoteric method of wine production.

READ MORE »

Growing & Winemaking

April 2017Grapegrowers Make Progress with Cold-Hardy Varieties

Growing cold-hardy grapes and making wine from them might be the ultimate lifelong learning process, if the sessions at the Cold Climate Conference held Feb. 16-18 in Bloomington, Minn., are any indication. But thanks to the work of researchers and educators, many of whom drew standing-room-only audiences for their presentations at the conference, the learning curve has gotten a little less steep.

READ MORE »

Growing & Winemaking

March 2017How Wineries Use Vineyard Technology

A Google search for the exact phrase “wines are made in the vineyard” produced 40,600 results, making it one of the industry’s mantras, along with “our Chardonnay is buttery” and “I thought we’d be cash-flow positive by now.” All overused, yet accurate.

Since much of winery success and wine quality is based on grape quality, I interviewed several winemakers and viticulturists about what they currently do in the vineyard to enhance wine flavor and assure consistency from year to year. They shared with me what data they collect, cropping levels, harvest criteria and advanced technologies employed.

Rodney Strong Vineyards

READ MORE »

Growing & Winemaking

March 2017A Conversation with Jim Barbour

Jim Barbour, one of the Napa Valley’s leading viticulturists, grew up on his family’s Rutherford vineyard. The Barbours grew Gamay, Mondeuse and Petit Bouschet that E. & J. Gallo Winery harvested for its jug wine program. They also farmed stone fruit and walnuts, but the future of the valley was wine grapes, so that became the Barbours’ focus.

The young viticulturist’s childhood chores focused on the farm, so when he went to college, he planned to try something new: being a parole officer. He quickly decided that wasn’t the career for him, however, so he went back to what he knew. He transferred to the University of California, Davis, and graduated in 1975 with a degree in plant science. While he was at Davis, Barbour would return home on weekends to drive a tractor for prominent viticulturist Frank “Laurie” Wood at Frank Wood & Sons. After graduating, he went to work for the company full time until Wood’s retirement in 1990. Barbour then started his own management company, Barbour Vineyards. In his 40-year career, Barbour has planted and managed some of the valley’s best and best-known vineyards and has worked with winemakers such as Celia Welch, Heidi Barrett, Philippe Melka, Aaron Pott, Thomas Brown and Martha McClellan. He currently manages about 500 acres of vineyards for various clients including Hundred Acre, Revanna, Jones Family, Checkerboard, Tietjen, Keever and Alejandro Bulgheroni.

In 1995, Barbour launched his own Barbour Vineyards wine brand, for which Welch is the current winemaker. The label produces 300 cases of dry-farmed Cabernet Sauvignon from Barbour’s 4-acre vineyard in southern St. Helena. Barbour is also a partner with Barrett and John Schwartz in Au Sommet, a project on Atlas Peak.

Q: What new vineyard technologies are you most excited about?

READ MORE »

Growing & Winemaking

January 2017A Conversation with Jared Brandt

Jared and Tracey Brandt of Donkey & Goat winery in Berkeley, Calif., were working for tech companies in the San Francisco Bay Area when they decided to take a one-year sabbatical in 2001. They loved wine, so rather than simply travel for a year, they went to France to study winemaking under Eric Texier, a respected winemaker in the Rhône Valley and Mâconnais regions who was committed to “natural” viticulture and winemaking.

READ MORE »

Growing & Winemaking

January 2017The Radical Reshaping of Babcock Vineyards

Since 2008, Bryan Babcock in the Sta. Rita Hills AVA of Santa Barbara County, Calif., has radicallyreshaped Babcock Vineyards using a new approach he calls “pedestular cane suspension” (PCS), which has reduced vineyard costs by 25%. Babcock coined the term “pedestular” to note the innovative use of metal pedestals that support and contain the vine’s fruiting canes and support the subsequent crop.

READ MORE »

Growing & Winemaking

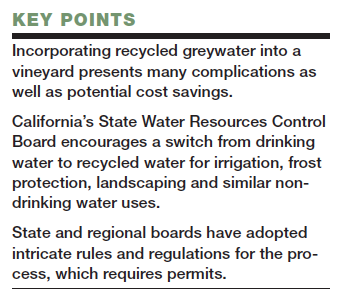

January 2017Fifty Shades of Greywater

California is in the midst of an unprecedented water crisis. In 2014, the U.S. Government Accountability Office reported that 40 states expect water shortages during the next 10 years. To help, the recycled water movement is steadily flowing as vineyards search for new sources of water to be used for irrigation, frost protection, landscaping and other operations. A news item in the June 2016 issue of Wines & Vines highlighted a new water-conservation opportunity for the Carneros American Viticultural Area: receiving recycled water for vineyard and landscaping irrigation from the recently completed Napa Sanitation District’s “purple” pipes. (See “Recycled Water now an option for Napa Vineyards.”)

This article takes up where that one left off and discusses the feasibility and complications of incorporating recycled greywater into your vineyard, including the types of permits required, the use and discharge limitations, required monitoring and reporting, recycled water use agreements and, finally, where to seek funding. This is a practical introduction for wineries and vineyards to the convoluted, multi-layered pool of greywater reuse.

READ MORE »

READ MORE »

Growing & Winemaking

January 2017Start Planning Equipment Purchases Now

January in the winery. Harvest is in the rearview mirror, and wines are aging or getting ready for bottling. You had some time over the holidays to get reacquainted with your family and resume a normal sleep schedule. The last thing you want to think about is next harvest, but if you plan to buy new crush equipment, now is the time.

READ MORE »

Growing & Winemaking

December 2016Majority in Napa to Replace Vines by 2017

Napa, Calif.—Pressure from grapevine red blotch-associated virus and Pierce’s disease is one of the mainreasons most Napa County wine grape growers plan to redevelop vineyards by 2017.

READ MORE »

Growing & Winemaking

December 2016Researchers Dispute Theory About Low Yields, High Quality

Napa, Calif.—The universal rule about lower yields producing better wines has been pretty well debunked by scientists, but it hasn’t been accepted by all winery marketing personnel (and some winemakers) who insist lower yields equal better quality.

READ MORE »

Growing & Winemaking

November 2016Advances in Enzymatic Analysis Technology

I last wrote about several laboratory analyses testing for important wine and grape constituents using enzymatic protocols measured spectroscopically in April 2014. Since that time, Megazyme introduced a new spectrophotometer called the MegaQuant Wave.

In addition to this new entrant designed for small to medium-sized wineries, two other instrument producers are competing in this segment of the market. The instruments are discussed in the order of price of market entry; check with each manufacturer for their exact costs.

Prior to the introduction of purpose-built instruments, incidental users of enzymatic analysis had to use basic spectrophotometers. These instruments had significant limitations, not the least of which was that the user had to do the calculations by hand and use equations that many in the wine industry did not feel comfortable computing.

The harbinger of the effort to supply a purpose-built, small-format enzymatic analysis instrument for smaller wineries was the Monza analyzer from Randox. This instrument was featured in the April 2014 Wines & Vines article mentioned above. Astoria-Pacific, another company in this market area, has offered a larger format, purpose-built system for many years that is a step up in sophistication from the Randox Monza. It has an auto sampling system and is useful for wineries that have a higher volume of analyses on a regular basis.

In the past, the most cost-effective means of analyzing wine constituents using enzymes was to buy a simple spectrophotometer such as the Spec 20, originally produced by Bausch & Lomb but now sold by Thermo-Scientific. The key to this instrument’s operation was a diffraction grating that split the incoming light source into discrete narrow bands of light (10 nm or less) and measured by a photometer. This instrument was designed to study between 940 nm and 340 nm wavelengths of light. For many enzymatic analyses, the most

READ MORE »

Growing & Winemaking

October 2016Brand Differentiation Is the Key to Success

Bokisch Vineyards set itself apart through its ?dedication to Spanish grape varieties.The book Blue Ocean Strategy, authored by W. Chan Kim and Renée Mauborgne, makes this observation: “Today’s overcrowded industries competing head-on results in nothing but a bloody red ocean of rivals fighting over a shrinking profit pool. Lasting success comes not from battling competitors, but from creating blue oceans of untapped new market spaces ripe for growth.” Brands that are different can grow much more easily because their market is a big blue ocean.

This slogan from a paradoy motivational poster could have been written about the wine business: “Conformity: When people are free to do as they please, they usually imitate each other.” Common wisdom states that you must revere tradition and do things “the way the wine industry does it.” Yet many of the most successful California brands did just the opposite. Kendall-Jackson made its Chardonnay slightly sweet. Purists said the winery wasn’t making Chardonnay the “right way,” but brand-loyal consumers loved it. It has had enormous success. The point of differentiation could be a new varietal such as Bob Lindquist of Qupé pioneering Syrah in the 1980s, or a new appellation like Steve and Pamela Storrs’ dedication to the Santa Cruz Mountains.

What is your story, your mission? So often a winery’s “About Us” page reads like this: “It was the dream of wealthy corporate-types and wine lovers Jane and John Doe to someday plant a vineyard, build a winery and make hand-crafted, artisan wines. Several years later, that dream has come true, with our ostentatious winery building making the cover of Modern Narcissist magazine.” (OK, I made up that last part.)

While this prose appeals to the owners, it is unlikely to connect with consumers. They don’t react by thinking, “Oh, you’re already rich and always wanted your name on a wine label, I feel a connection! Sign me up for the 12-bottle wine club.” I would argue that if wanting to be in the wine business was your reason for being in the wine business, then you have completed your mission. The problem is your mission wasn’t focused enough on creating a differentiated business. It may be why your tasting room is empty, your wines aren’t selling and you are low on cash.

Every year I give a guest lecture about entrepreneurship to students in Napa Valley College’s wine program. I ask a few students to describe the winery where they work and its Chardonnay, if they make one. The first student says something like, “We’re a family winery, very dedicated to making great wine. We believe wine is made in the vineyard. Our Chardonnay is barrel fermented in the traditional French style.” The second earnestly explains, “I too work for a family winery, very dedicated to making great wine; our Chardonnay is barrel fermented, etc.” The third says essentially the same thing, maybe subbing Cabernet made in the Bordeaux style for Chardonnay. I then ask the rest of the class which one they’d buy. The answer is, “I don’t know, they all seem pretty good.” Regardless of wine quality, the brands are undifferentiated commodities to the consumer.

Let’s look at a few wineries that found success through brand differentiation.

A visit to Catalonia

READ MORE »

Growing & Winemaking

September 2016California Crop Forecast: 4 Million Tons

Credit: Ashley Urdang/Gloria Ferrer

Credit: Ashley Urdang/Gloria FerrerAllied Grape Growers president Nat DiBuduo believes that the 2016 crop “seems to be getting smaller,” to the tune of 4 million tons expected in California.

Speaking at the 64th annual meeting of the Allied Grape Growers in July, DiBuduo told the audience that while Allied Grape Growers is still compiling estimates, it appears total tonnage in California will be about 4 million tons. This is below “average” after a number of big years (excepting the short harvest of 2015), but it’s not clear what average is with new plantings producing higher yields.

Allied Grape Growers held events in the California cities of Fresno and Santa Rosa to accommodate the group’s members in both regions. Wines & Vines attended the meeting in Santa Rosa (in the North Coast), where Allied Grape Growers had roughly 1,500 acres under contract in 2010 and represents more than 2,500 acres today.

Unlike the 2015 meeting, this gathering was mostly upbeat. “Some years I would rather be having a tooth pulled than face you with the news,” said president and CEO Nat DiBuduo. “Last year was one of those years.”

Fortunately, things are going well for the grape marketing cooperative, which has nearly 500 members including 125 member-growers in the North Coast, 50 in Lodi/Clarksburg and Contra Costa County and 300 in California’s interior valleys.

Allied Grape Growers has members across the state, from southern Kern County up to Clear Lake in Lake County. So far this year, grapes have been contracted from $275 per ton to $7,500 per ton or higher, depending on location and variety, DiBuduo said. He disclosed that the co-op’s revenue for 2015 was more than $70 million.

In Lodi, the co-op has experienced more than 37% growth in wine grapes since 2010. There were fewer growers at the co-op’s Central San Joaquin Valley meeting; many pulled out their Thompson Seedless vines or sold their ranches, but wine grape acreage has still grown 50%.

DiBuduo admitted he received a lot of criticism at the Unified Wine & Grape Symposium in Sacramento, Calif., this January, when he suggested growers needed to pull out more wine grape acres.

“No wine grape grower should be providing grapes below their cost of production. You are in the business to survive and thrive. So if I can save any grower from going bankrupt by suggesting alternatives or getting better pricing, I will.”

He summarized the overall market for California wine grapes:

“North Coast is the shining star in this industry. The current demand is outpacing the supply. There are strong prices and terms. Some wineries are offering planting contracts for the first time in years.”

Central Coast prices appear to be strengthening. The supply is limited there. “We see some contracts for Pinot Noir and Chardonnay.”

DiBuduo said that, while it’s early in the season, Lodi growers are enjoying strong sales, and most grapes are finding homes. There is a limited supply available of red Zinfandel and some other varieties.

In the central San Joaquin Valley, however, some varieties like Muscat, Ruby Cabernet and white Zinfandel continue to be challenged. “We have plenty of those for sale,” he said. “The good news is that in August of last year, we had over 20% left to sell. This year we have less than 10% left.”

A push for ‘premiumization’

READ MORE »

Growing & Winemaking

August 2016California Law Regulates Piece-Rate Payers

A new California law that went into effect in January 2016 presents problems for employers who pay their workers piece-rate (rather than hourly) wages. AB 1513 requires companies to separate piece-work compensation from rest and recovery (R&R) breaks and other “non-productive” time on the job. Repayment plans were ordered to be in place by July 1.

Piece-rate compensation is popular with productive workers and with employers, especially in this era when skilled vineyard workers are in short supply and high demand in California.

Although statistics were not available, according to Tyler Blackney, director of government relations for the California Association of Winegrape Growers (CAWG), “A lot of people do piece work. A lot of workers like it. This law will make it more complicated. I don’t know how HR (human resources) people will track it.”

Blackney said that back pay would amount to six figures for some agriculture companies. Factoring in California’s recent minimum wage increase, “It will be hard for some vineyards.”

He stated: “This new piece-rate legislation is going to result in a number of our growers paying a substantial amount to avoid liability. Some are facing six-figure payments. That is a lot of money. Moving forward, piece rate is going to be used less frequently, because growers are not going to want to face the future liability for doing it wrong. It’s a shame because workers prefer piece rate: It provides them an option to maximize their profits over a shorter period of time.”

Grapegrower calls ‘foul’

READ MORE »

Growing & Winemaking

August 2016Closure Decisions Are More Than Technical

Eleven years of “cork wars” combat experience (I was founder and president of Neocork, a synthetic cork pioneer) gave me insight about closure decisions. It failed to give me wealth, just insight. I am rich with insight.

Some might say that having “a synthetic cork guy” write this story is like letting Elon Musk write an objective comparison of electric vs. gas vs. diesel cars. It’s been more than 10 years since I’ve worked for or had a financial stake in any closure company. I’d like to think that time has mellowed rather than “tainted” me (pun apology No. 1.).

When I started with alternative closures 22 years ago, one-piece natural corks were the standard, with twin-disk corks used for value-priced wines. Cork quality attributes were primarily cosmetic: A pretty cork was a good cork. A gorgeous cork was a great cork and cost more. Screwcaps were used on jug wines only. There were no acceptable synthetic corks that worked, plus they had a huge image problem. Winery owners and marketing directors were certain that the moment they sealed a wine with something other than tree bark, their wines would be immediately removed from every wine list and store shelf in the country—and worst of all, they’d personally be found guilty of the scandalous crime of breaking with the industry’s traditions of “how we do things.”

What I’ve learned over the years (and what Jane Firstenfeld’s article on page 36 confirms) is that no one closure type is the undisputed “winner,” nor are any of them fundamentally unacceptable. Around the world in the next 24 hours, several million screwcap-sealed bottles will be opened and enjoyed, as will several million bottles sealed under synthetic cork.

Focus on the consumer

READ MORE »

Growing & Winemaking

July 2016Winemaker Interview: A Conversation with Jeff Meier

Winemakers are often peripatetic types, changing jobs every few years. Not Jeff Meier. The director of winemaking at J. Lohr Vineyards & Wines has been with the company (which has wineries in San Jose, Paso Robles and Greenfield, Calif., and farms 3,700 acres of vineyards) for more than three decades.

READ MORE »

Growing & Winemaking

July 2016Capitalizing on Winemaking Waste

Waste flows from the winemaking supply chain contain wastewater (generally treated inside the winery or sent to municipal plants via sewage systems or by truck) and solid waste such as stems, pomace and lees. In Italy the stems were traditionally used as soil amendments, while for years the pomace and lees have been delivered compulsorily to distilleries for the production of alcohol and the recovery of tartaric acid.

Regulation EC 479\2008 of the European Union introduced important new elements to the legal framework of the wine sector, offering member states the possibility of defining the end use of pomace. Italy implemented the above regulation by means of a ministerial decree, which, as an alternative to distillation, allows it to be collected under control for the recovery of enocyanins (anthocyanins responsible for the color of red grapes), the production of agricultural products (direct or indirect agronomical use), energy recovery (using byproducts such as biomass for the production of biogas or for fueling energy-production plants) and the extraction of molecules with a high added value for pharmaceutical and cosmetic purposes.

Direct agronomical use of these waste flows is a choice to be made under careful control and is inevitably subject to the dictates of legislation related to nitrates. In fact, it should be taken into account that the presence of polyphenols (antimicrobials), salts, heavy metals and nitrogen in these highly biodegradable wastes can compromise the quality of the receiving soil in the long term. Moreover, polyphenols inhibit germination and immobilize nitrogen in the soil.

Treatment of these wastes is fundamental, but it can be a significant cost for a winery. In fact, the high chemical and biological oxygen demand values highlight the high consumption of oxygen associated with their decomposition and therefore the risk of establishing conditions of anoxia in soils and rivers.

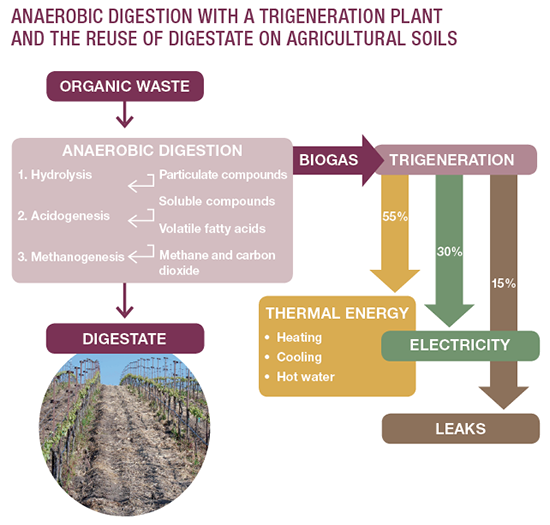

Biogas from anaerobic digestion

READ MORE »

Growing & Winemaking

July 2016The Hyde-Hobbs Partnership

Larry Hyde (left) and Paul HobbsA quarter-century ago, vineyard owner Larry Hyde and winemaker Paul Hobbs launched a partnership that inspired them to farm one of the first blocks of Hyde Vineyard Pinot Noir collaboratively. Hobbs agreed to pay Hyde for the grapes based on expected yield, not how much fruit he harvested. “If the crop looked too big and Paul wanted to drop fruit,” Hyde says, “he took the risk.”

But before the growing season began, Hobbs walked the vineyard in the Carneros district of Napa Valley with Hyde to determine which varieties and vineyard blocks he wanted to farm. According to Hyde, the agreement gave Hobbs and 40 other winemakers who signed similar contracts “leeway to grow exactly what they want.”

Together, Hyde and Hobbs carved a path to explore the character of the 152-acre vineyard that the Hyde family cleared in 1978 and planted in 1979. “I experiment with climate, soil and farming practices with every vintage,” Hyde says. “I learn something new from every producer, every variety, every year.”

For winemakers like Hobbs, Hyde returned the favor. “I was hungry for knowledge,” Hobbs says, “and sitting at Larry’s table was the place to be.”

Lay of the land

READ MORE »

Growing & Winemaking

June 2016It's OK to Plan: Preparing for Harvest

Hiring staff and ordering equipment and supplies well in advance of harvest can make the busy season (seen here at Herzog Wine Cellars) go more smoothly.

Hiring staff and ordering equipment and supplies well in advance of harvest can make the busy season (seen here at Herzog Wine Cellars) go more smoothly.Well, it’s June at the winery, which means you are probably getting ready to bottle some wines, finalize grape contracts and squeeze in a vacation before the madness of harvest begins. June is also an ideal time to plan for harvest. For many winemakers, planning for harvest means the following:

a. Spend a few hours online researching your vacation, checking out hotels, restaurants, tourist attractions, best places to fish, etc.

b. Walk through each of the vineyards that supply your winery. The typical two-hour visit is split into 30 minutes walking through the vineyard and actually assessing the vines and 90 minutes listening to the vineyard manager complain about how tough grapegrowing is this year, because it’s about the worst year he/she has ever seen for (insert vineyard malady or climate attribute here).

c. Make an unfounded tonnage estimate.

d. Remember that just as last harvest ended, you and your cellar crew made a “to-do list” for next year, vowing that 2016 would not be a repeat of “the great 2015 train wreck.” There was a list of spare parts needed, equipment that required major servicing, winery layout changes for better material flow and supplies that need to be ordered a lot earlier than you did.

e. Unfortunately, you pinned the to-do list to a corkboard, which has since been taken down. You now spend a few hours looking for it. You ask the cellar crew if they remember where it may have gone.

f. You give up on finding the to-do list. Rationalize to yourself that it’s not really that important. 2016 won’t be like 2015 because, well, just because.

g. Go back to planning your vacation.

The above scenario may be exaggerated, but having been a winemaker for small wineries and observing many winery operations, my sense is that winemakers spend a lot of time in the vineyard, but not quite enough time getting the winery ready. Harvest is crazy busy, which is why getting ready for it is so critical. One stuck thermostat can prevent a tank from chilling and cause an overnight fermentation spike to 95° F, with serious wine quality implications. Veteran winery operations managers know this, so they test and clean every tank thermostat prior to harvest.

What do “the pros” do? I interviewed three veteran winemakers about preparing for harvest, inquiring about planning tools, preventive maintenance schedules, staffing, ordering supplies, equipment and barrels, plus forecasting tank usage.

Continuity at Groth

READ MORE »

Growing & Winemaking

May 2016The Proof Is in the Pruning: Early Season Canopy Assessment

One- and two-bud spurs are evenly distributed on a vine with vertical shoot positioning (VSP) trellising.

One- and two-bud spurs are evenly distributed on a vine with vertical shoot positioning (VSP) trellising.Bud break and young shoot growth occurs rapidly across winegrowing regions, and warm temperatures hasten the workload for vineyard-management crews. Canopy management, shoot thinning and selective shoot removal are on the minds of most growers at this time. It is easy to get lost in the details of the next task when shoots are growing rapidly, but let’s not miss the opportunity to take a critical look back at the pruning work that has occupied the past few months.

Pruning is arguably the most important vineyard task. If done properly, it will greatly improve vineyard management during the season. A critical assessment of your pruning job is best accomplished between bud break and bloom. Hence, the proof of success of your pruning strategy is by now (or soon will be) evident.

Bud count vs. shoot number

READ MORE »

Growing & Winemaking

May 2016A Conversation with Ryan Harms

When Ryan Harms started classes at Binghamton University in upstate New York, he planned to become a doctor. But during his sophomore year, “Organic chemistry kind of did its damage.”

READ MORE »

Growing & Winemaking

April 2016Suppliers, Industry Seek Clarity on Yeast Sales Tax

The total global yeast market is estimated to grow to $4.3 billion by 2020. Winemaking is the third-largest use of yeast behind baked goods and brewing.

The total global yeast market is estimated to grow to $4.3 billion by 2020. Winemaking is the third-largest use of yeast behind baked goods and brewing.Given oxygen, stable temperatures and a supply of sugar, yeast will happily get to work powering a fermentation.

And perhaps at the microbial level, the yeast do not even perceive a difference between fermenting beer and wine. In California’s capital city of Sacramento, however, the state department that applies sales tax did see a difference between yeast used for brewing and yeast used for winemaking: Wine yeast was subject to sales tax, while brewing yeast was not.

According to the California State Board of Equalization (BOE) sales tax annotation 440.0780, selling yeast to wineries was taxable because “yeast is used in the manufacture of wine in order to bring about the fermentation process and is not used for the purpose of physically incorporating it into the wine.”

Annotation 245.1101 stipulates, “Tax does not apply to the sale of viable yeast, which is sold as a food for human consumption in the production of bread and malted alcoholic beverages such as beer, mead and ale.”

The difference, according to the state BOE, is that “yeast for wine is not incorporated, and thus, not consumed by humans.”

Earlier this year, however, an attorney with the BOE made the unexpected decision that the viable yeast sold for winemaking is in fact a food product and should not be subject to a sales tax. Suppliers and industry representatives had been pushing for a change for years but made little progress with the state.

Winemaking to get a little cheaper

READ MORE »

Growing & Winemaking

April 2016Terroir and Other Myths of Winegrowing

Editor’s note: Terroir and Other Myths of Winegrowing explores popular winegrowing concepts including yield, berry size, vine balance, a critical ripening period, and terroir. The book is currently available from the University of California Press (ucpress.edu). The following excerpt from Terroir and Other Myths of Winegrowing explores popular concepts related to wine quality and crop yield.

READ MORE »

Growing & Winemaking

April 2016Packaging Planning Is Critical for Bottling Day

Start planning for bottling day six months in advance if you have used your suppliers before and 12 months ahead for new products or items that are going to require design work.

Start planning for bottling day six months in advance if you have used your suppliers before and 12 months ahead for new products or items that are going to require design work.Here’s an example of two ways to solve the same problem.

1. You need open heart surgery. You have a surgeon (probably a highly recommended referral from your primary care doctor). He or she works with a hospital to book a time and date; all the doctors, nurses, tools, supplies and equipment are in place on the day of your surgery. You defer to their planning and expertise. You eat nothing the night before. The system works. You live a long time and get to meet your grandchildren.

2. You need open heart surgery. You call a few hospitals to see who has open surgery rooms. Your No. 1 priority is to get a good price, because, “Hospitals are a commodity, and it’s my money!” Then you hire a doctor, bring in some nurses from a temp agency who also gave you a heckuva deal, buy scalpels, bandages and oxygen tanks from a range of vendors (you get to go on one vendor’s annual fishing trip if you buy from them), and tell them all to ship to the hospital the day before your surgery date. You don’t ask the hospital which surgery supplies they recommend. A scalpel is a scalpel. Also, you hate the idea of surgery almost as much as you hate bottling wine, so you don’t waste time keeping tabs on your suppliers to see if they will make their delivery dates. Surgery day arrives and…

Wine quality matters. You must have an executed package that’s worthy of that wine and its price, but that can’t happen until it is safely bottled with a closure, capsule, TTB-approved label and shipping case. And that’s the bare minimum. Do you remember the scene from the film “Office Space” when the manager of Chotchkie’s restaurant scolded Jennifer Aniston for wearing only 15 pieces of flair? “What does that say about you, just doing the minimum?”

My premise is that designers, materials vendors and bottling services vendors must collaborate on behalf of winery and brand owners. When that doesn’t happen, it’s usually not because they don’t want to do it, but because the winery doesn’t see planning as a critical and collaborative process with potentially divergent criteria for each vendor (e.g., cost, quality, speed).

Winery owners should note that when bottling day problems arise, winemakers will likely blame vendors for their “crap (insert packaging supply here)”, yet a more objective assessment might be that the winemaker planned poorly.

Learning from wineries

READ MORE »

Growing & Winemaking

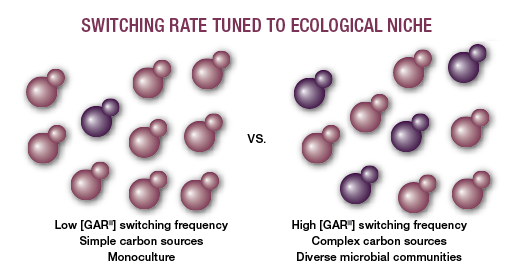

March 2016The Role of Bacteria in Stuck Fermentations

Hundreds of articles about stuck fermentations cover how to avoid them as well as restart them. It is an art that relies on experience and intuition about what went wrong with a particular fermentation. The traditional methods that help to avoid stuck fermentations include assessment of spoilage organism potential, nutritional status of the initial must and viability of the yeast used relative to the style of wine desired.

Many laboratories servicing the wine industry offer assessment panels to test a winery’s grapes, but in most cases winemakers don’t use that service until it is too late. The sooner the winemaker understands there is a problem, the easier it will be to begin a triage of the situation and the better the resulting wine will be.

Even when a winemaker thinks all bases are covered, occasionally fermentation for a certain wine won’t perform the same way it did in previous seasons. As a wine consultant and winemaker, this has always been a bothersome situation to resolve: Why would this wine, this season, not complete fermentation? This was the case with wines from a recent client of mine. The winery had a series of wines with fermentations that had started normally. Then, sometime after the lag phase had passed and the yeast was on the concluding side of the fermentation curve, the rate slowed to a crawl and apparently stopped at about 2° Brix. After trying all the traditional paths to restart the fermentation, they asked me to figure out what might be causing this situation.

When I reviewed the wines organoleptically, I found no off odors. Analysis showed volatile acidity was below any threshold and, therefore, not a problem. VA is one of the more frequent causes of stuck fermentations at this level, and remedial efforts that would exacerbate that situation should be avoided.

However, one of the techniques the client had tried was to introduce lysozyme, which is frequently added to reduce the bacterial load in a fermentation. Lysozyme is most effective against gram-positive bacteria, which meant that after the lysozyme addition, the wine still could have had Acetobacter or other acetic acid-producing bacteria present.

Macro oxygenation is a technique frequently used to help fermentations. Yeast are facultative organisms, meaning they can survive both in aerobic and anaerobic environments. In a normal fermentation during lag phase, yeast grows rapidly and lives off the dissolved oxygen that is in the must. Eventually the organism population exceeds the capacity of the must to bring more oxygen in from pumping over, and so the yeast switch from aerobic metabolism to anaerobic metabolism. That is when augmentation of yeast growth is helped by injection of up to 60 mg/L per day of oxygen into a must, which can encourage the yeast to continue to grow at maximal rates. This technique is not without some peril, as Acetobacter are not facultative organisms. Withdrawing oxygen slows and then stops growth of the acetic acid bacteria during fermentation.

If you know that there are Acetobacter organisms present, you need to monitor any additions of oxygen to maintain the health of the wine. It was with much caution that I broached the possibility of adding oxygen to these fermentations. At this time I remembered a news brief published by Linda Bisson from the University of California, Davis, about a new concept of yeast metabolic regulation by bacteria that involved prions.

Use of the environment

READ MORE »

Growing & Winemaking

March 2016A Conversation with Markus Bokisch

Markus Bokisch

Markus BokischMarkus Bokisch, owner of the vineyard-management company Bokisch Ranches in Lodi, Calif., isn’t the area’s largest grower. He is, however, considered one of its most influential.

READ MORE »

Growing & Winemaking

January 2016Top Seven Mistakes New Grapegrowers Make